Contour Crafting (CC) is a layered fabrication technology developed by Dr. Behrokh Khoshnevis of the University of Southern California. The technology has great potential for automating the construction of whole structures as well as sub-components.

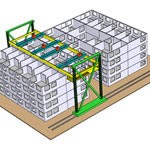

Integral to the process is a computer controlled crane or gantry that builds houses or structures with the Additive Manufacturing (AM) process of layer-by-layer construction.

A single house or colony can be constructed with each house unique in design. Floors and ceilings are set in place by crane with electrical, plumbing, air-conditioning and other features implanted between layers. It is estimated a 2,000 square foot house with all utilities can be constructed in less than 24 hours.

The layered fabrication technology has the potential to provide a viable solution for emergency and low income housing, space colonies and other commercial applications.The technology can fabricate small and large scale parts quickly using concrete like material or others readily available at the build site. Advantages of the process are superior surface finishes of the completed construction, enhanced speed of fabrication, minimal material waste, minimum labor and related construction injuries.

CC Fabrication

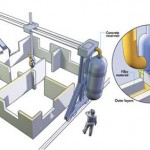

The CC process combines ancient surface forming concepts with modern robotics technology.

CC Testing

Flow pattern comparisons using various orifices complete with simulation analysis.

CC Nozzle

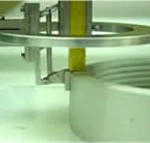

Movable side trowel with various surface slopes.

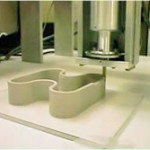

CC Build Samples

Our sincere appreciation to Dr. Behrokh Khoshnevis for permission to publish content of this exciting AM fabrication process.

Center for Rapid Automated Fabrication Technologies (CRAFT)

Professor, Industrial & Systems Engineering

Aerospace, Mechanical, Civil and Environmental Engineering

University of Southern California, Los Angeles, California