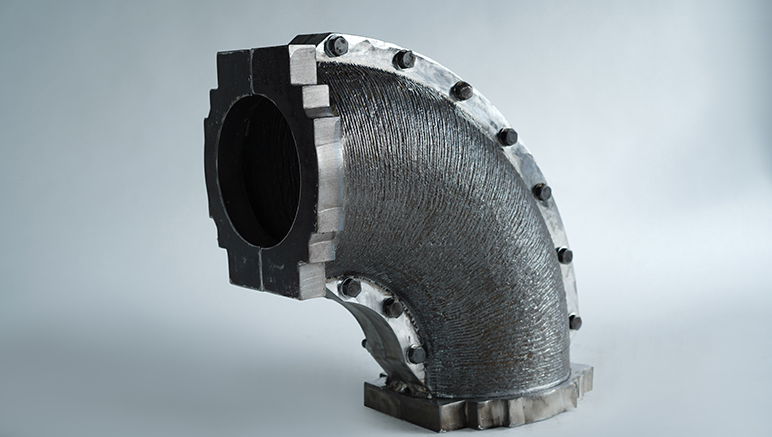

MX3D, Team and Tiat reveal 3D printed pipeline clamp

Amsterdam, The Netherlands – November 3, 2021 – MX3D, a Robotic Wire Arc Additive Manufacturing (WAAM) company, successfully completed the printing of an industrial pipeline clamp. Clamps like these are used in the Chemical and Oil & Gas industries to prevent incidents and to increase the run time of an installation before maintenance is required.

The WAAM Clamp is made and tested in collaboration with Team Industries and TiaT, two companies with extensive experience in the maintenance, testing and (emergency) repair of complex industrial pipe systems. The BWI (Belgium Welding Institute) handled the material testing and Lloyd’s Register supported MX3D with the certification process.

Short lead times are key in the oil and gas industry, as both reducing production downtime and decreasing environmental, human and safety risks are critical. The current lead time of pipeline repair can be as long as 2 to 3 weeks with a potential lost value of several 100k to 1M EUR per day. Current repair processes by clamps typically rely on CNC milling, specialized manual labour, or a combination of both. Each of these processes have their downsides, as CNC milling has high material waste (on average >80% of the original material) and specialized labourers are becoming more scarce.

During the scope of the WAAM Clamp project, a typical repair part for pipelines has been researched and manufactured with hybrid WAAM. This technique provides a smart production solution, by combining the advantages of traditional manufacturing (such as precision machining) with the advantages of wire arc additive manufacturing (such as form freedom, high deposition rates and minimal material waste).

The consortium managed to reach a high level of assurance for the WAAM clamp. BWI tested the materials and confirmed the printed material complied with key TEAM Industries requirements for this material. The MX3D M1 Metal AM System, facility and procedures were qualified by Lloyds Register. TiaT performed non-destructive testing, such as Ultrasonic Testing (UT), Penetrant Testing (PT), Radiographic Testing (RT), showing no relevant defects. TEAM Industries has performed a pressure test, which ran until the maximum pressure of the test installation (i.e. > 60 Bar) without any failure.

The base and printing material used was ASME IIA SA-516-70, a type of steel often used in the Chemical and Oil & Gas industries. The requirements for the mechanical properties of this material were dictated by its most common use case: pressure vessels working at medium to low temperature. The destructive tests were performed following ASTM A370. The destructive testing results proved that the printed material, even in its least favourable direction, has mechanical properties similar or better than the base material, hence fitting the ASME requirements.

The project introduces Hybrid WAAM, a new approach to counter two known disadvantages of additive manufacturing, namely the need for post-processing and precision. While large scale additive manufacturing can produce parts very fast, traditional manufacturing techniques can sometimes still be faster for the production of simple shapes. Conventional techniques can also achieve a higher level of precision than large scale AM. By introducing a hybrid approach, the project consortium used 3D printing only for the most complex geometrical parts of the clamp, while using traditional manufacturing for the simpler parts, saving precious time.

Hybrid WAAM has several advantages over conventional technologies such as forging, CNC-milling and manual welding (requiring speciality welders) for the oil and gas industry. Compared to forging, WAAM has a shorter fabrication lead time as it can produce local, on-demand and at remote locations. Compared to CNC-milling, WAAM has a much lower material waste due to using an additive manufacturing process instead of a subtractive process. Finally, compared to manual welding, the manufacturer is less dependent upon the availability of speciality welders, as robots can fabricate 24/7. By incorporating pre-manufactured standard components into the WAAM process (i.e. Hybrid WAAM), each of the above-described benefits are increased by reducing lead time and manufacturing time compared to regular WAAM.

The project will be on display at the MX3D booth, 16-19th of November during FormNext 2021 in Frankfurt (Germany), Hal 12.0 Booth C81.

The project received support from the EU Horizon 2020 program, through the 1st call for TRINITY Demonstration Programme, Project full name: Digital Technologies, Advanced Robotics and increased Cyber-security for Agile Production in Future European Manufacturing Ecosystems, Acronym: TRINITY, EU Horizon Grant agreement number: 825196.

About the consortium:

MX3D | Robotic 3D Metal Printing

The Dutch company MX3D develops robotic metal 3D print technology. MetalXL is an intelligent proprietary software that turns an off-the-shelf welding robot into a high-end industrial 3D metal printer. The company also offers a turnkey solution with their M1 Metal AM System. Furthermore, the company provides printing and research services to companies that want to evaluate the role of Robotic Wire and Arc Additive Manufacturing (WAAM) within their industry. For more information, see www.mx3d.com.

Team Industrial Services

Team Industrial Services is a global leading provider of integrated, digitally-enabled asset performance assurance and optimization solutions. We deploy conventional to highly specialized inspection, condition assessment, maintenance and repair services that result in greater safety, reliability and operational efficiency for our client’s most critical assets.

Facility integrity threats such as leaks or wall thinning can be extremely costly to operators if left unresolved. TEAM’s world-leading on-stream leak sealing and mechanical repair group is available 24/7, adding value to customer operations by maximizing the availability of critical equipment, reducing steam-raising costs, minimizing environmental emissions and enhancing safety.

TiaT

A Dutch inspection company, based in Roosendaal with 20+ years of experience in NDT Training, Inspections and Engineering. TiaT Europe is your professional partner in the field of non-destructive testing (NDT) www.tiat.nl

BWI | Belgium Welding Institute

The Belgian Welding Institute (BWI) is an independent expert centre for welding technologies and materials weldability. Its activities cover a wide range of applied research projects, advice and testing services, as well as training courses. BWI supports companies in taking steps towards WAAM additive manufacturing of metals; from feasibility studies to integrating the technology into the production environment, as well as testing/standardisation issues. For more info: www.bil-ibs.be