Innovation is often defined as something new, perhaps invented, although not always. Scholars, corporations, and government agencies have their own definitions often centered on greater effectiveness and product improvements. Even the International Standards Organization (ISO) that guides so many engineering processes has the ISO 56000:2020 to define innovation management.

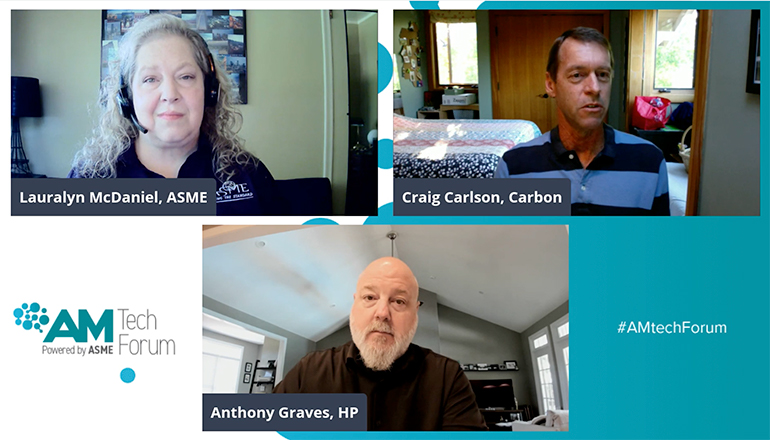

Without all the definitions and standards, most of us want to boil it down to this: Can we make something better or easier or faster? It is with that idea that the ASME created the AM Tech Forum Executive Panels, this one moderated by ASME’s Lauralyn McDaniel, AM Strategy and Engagement, an industry veteran.

If you are looking for thought leadership and latest trends in Advanced Manufacturing, visit the ASME Topics and Resources page. You will find a wide range of deep-dives on topics that are discussed in this panel (Lattice structures), as well as subjects, such as: On-Demand Additive Manufacturing Is The Future and Keeping Football Helmets Cool, to list just a few.

The panel on Innovation and Additive Manufacturing opened the Executive series by asking two corporate leaders what they were seeing out in the field.

- Craig Carlson, CTO for Carbon. He’s responsible for the short and long term technology needs of the company. His experience includes time as VP of software for Tesla Motors.

- Anthony Graves, head of product and strategy for HP, with a new initiative and group, digital manufacturing software, where he’s responsible for vision requirements, pricing and packaging partnership.

Some of the key highlights discussed in this session:

- Materials science and materials development

- Lattice structures and a deeper “tuning” or process refinement (combined with materials advances)

- Post-processing improvements – spinning parts clean

- Artificial Intelligence / Machine Learning (AI / ML)

Without materials advances, both panelists agreed, many of today’s additive manufacturing innovations would not be possible. Craig Carlson discussed how many of the lattice structures depend on materials advances: “There’s also high performance elastomers now that can be printed, and the ability to really tune for the performance that you need, whether it’s for energy dampening, or energy return, lightweight, is something where there’s been a lot of progress recently.”

According to the Wohlers Report 2021, lattice structures, and the software to improve and refine them is essential to advances outlined in the AM Tech Forum panel. Anthony Graves echoes these research findings in his on-the-ground expertise and their recently announced “Universal Build Manager” with Dyndrite:

“There have been innovations around software. I’ve just talked about a bunch of software companies around lattice and other areas, too… In the MES space (Manufacturing Execution Systems to make the AM workflow more easily manageable, by automating key processes like order management, production scheduling and monitoring), we think another area at HP, a huge area, is around automation. [This] ties back to what Craig was saying is one of the big areas that all the customers are looking at: how do you automate the cleaning of these parts, because right now, it’s been very labor intensive.”

Software automation for the creation of better lattice structures (topology optimization), materials advances, are available in the new Universal Build Manager which will be accessible and open for others outside of HP to use. This summary from HP on its UBM echoes all of the key points made during the panel event:

- Streamlined build preparation and reduced computational times with accelerated GPU technology

- Automated production processes—lowering production costs

- Improved part quality with print profiles optimized for specific processes, geometries, or materials

Finally, the audience had questions on artificial intelligence and machine learning that revealed a number of trends and insights from both panelists. AI and ML are fast becoming integral to AM with improvements to the value chain from material development, machine set up, part design, and workflow automation. AI is helping to select and refine materials used in a print job as well as how that material gets printed. Anthony Graves shares his thoughts as the panel discussion comes to a close:

“We’re teaching these computers how to try to think. But it makes sense, because one of the biggest challenges around material science and manufacturing, in general, when you’re doing product development is process development. And having the ability to iterate quickly, it used to be a you know, because otherwise, you’re just taking machine time, and you’re consuming material for what potentially is going to be a failed part or a failed design. And so, through computerized machine learning, I think that is going to allow us to get to the right processes, or at least get into the ballpark of where people need to focus their time and attention.”

AI is increasingly impacting, arguably at the concept level, with AM systems to enable greater process control and repeatability. Dyndrite is funded, in part, by Gradient Ventures (Google’s AI-focused venture arm) run by Carl Bass (former CEO of Autodesk), so there is clearly a trend in AI/ML taking a place at the AM table.

Craig Carlson confirmed that AI and ML were playing a part in their processes at Carbon, “With our process, in particular, knowing how to orient a part is important to get a good part out. And it’s very complicated to do that correctly. People have algorithms, other software companies have algorithms, our software has algorithms for trying to orient a part. But it’s complex enough that those algorithms often don’t do the best job. So that’s the place where we’re looking at machine learning to really help us get much better orientations out of a computer, so that a human doesn’t have to be an absolute expert to get the best orientation.”