With a group of technologies that was referred to as rapid prototyping in its earliest days, there doesn’t seem to be much discussion about prototyping today. Some may wonder if it is even a significant part of the applications of additive manufacturing. What about prototyping? Is it still a thing?

More than 15 years ago, I sat in a room of rapid prototyping leaders discussing how the technology was becoming so much more than prototyping and needed a more comprehensive designation. With the growth of rapid tooling and rapid manufacturing, the transition to rapid technologies seemed like the next step. At the time, additive manufacturing was being suggested as the overall term with Terry Wohlers being the leading supporter. (In 2005, 3D printing referred only to the binder jetting process developed by Ely Sachs at MIT.)

Enabled by many advancements in processes, materials, and software, the discussion today is very much about production and industrialization. Medical device and aerospace seem to be leaders in this effort. Aerospace’s need for low volume highly complex components along with fuel efficiency have found solutions using AM. For medical devices, particularly orthopedic implants, the unique design capabilities have allowed critical porous structures for bone ingrowth to be added more efficiently and added in ways that aren’t possible with more conventional manufacturing methods. This isn’t just for one-of-a-kind implants. Close to 200 medical devices (both metal and polymer) have received 510k clearance from the US FDA using AM as the primary production process. But…what about prototyping?

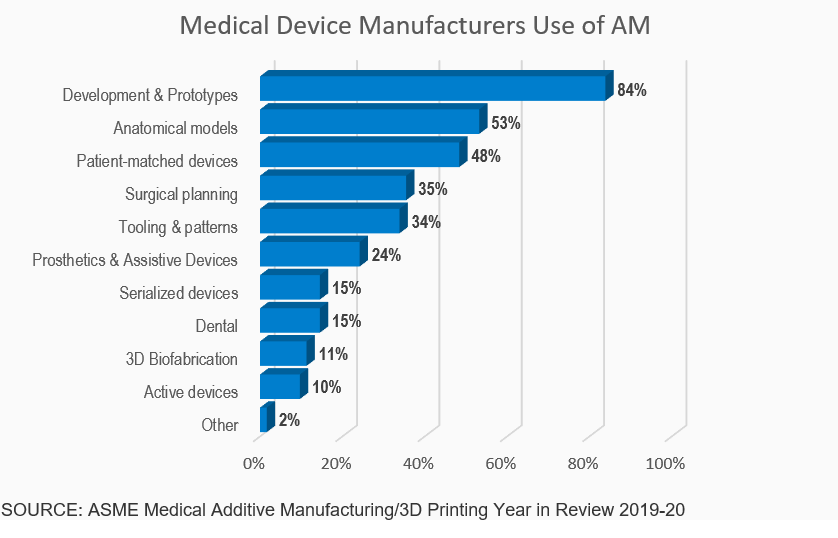

For medical device manufacturers, we do have an idea of how many leverage AM as a key component of their product development process. From the ASME Medical Additive Manufacturing/3D Printing Year in Review 2019-20, a survey indicated that 84% of device manufacturers use AM for prototypes.

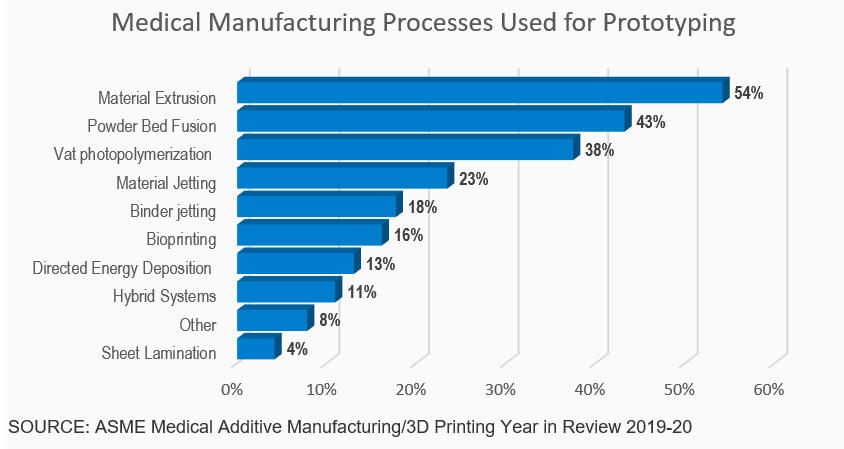

Almost every type of AM process and material is being used for prototypes. Polymer systems and polymer materials are the most used.

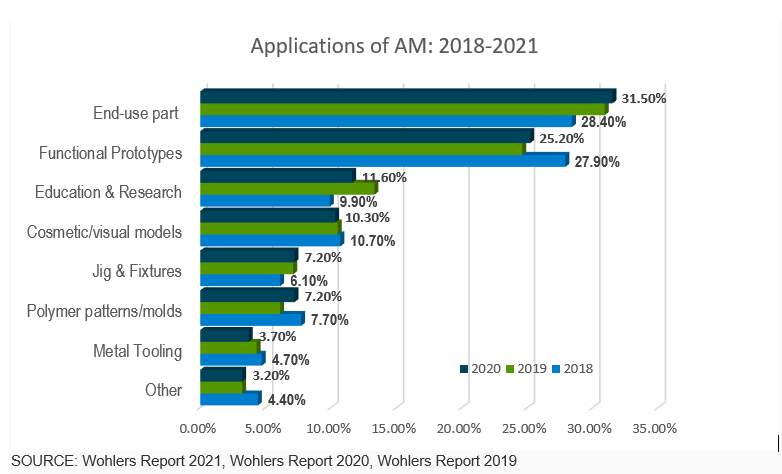

What about prototyping for all AM use? We can take a look at the recently published Wohlers Report 2021 3D Printing and Additive Manufacturing Global State of the Industry and compare to the last three years.

While end-use parts is the largest single application, if you combine functional prototype and visual models, total protypes represent 41.8% as the largest application area.

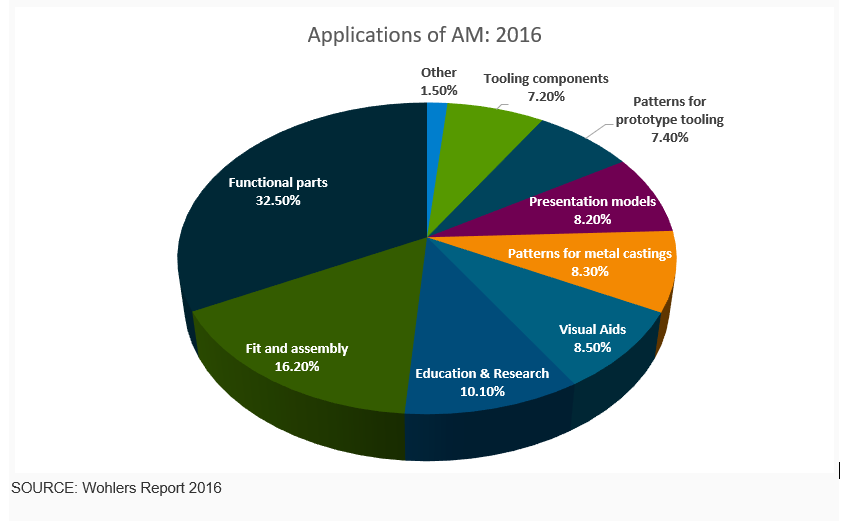

But why is prototyping not the leading application for discussion? If we take a look at the Wohlers Report from just five years ago, we can see how industry focus has changed. The applications categories in 2016 reflect a heavy prototyping perspective with different types of prototyping categories and seemingly both functional prototypes and end-use part in one category. As technology advances, the discussion evolves.

If the discussion has evolved, why bring prototypes back into the conversation? Those already using AM, understand the value and potential. Those not using may see the production story and hesitate to adopt the technology at any level. From the beginning, prototyping has been an entry point. Often the first use of AM is through collaboration with a contract manufacturer or an AM machine builder. Most of these will happily work with you to try a new process, a new material, or a new approach. With regular advancements and strong community users, now is the perfect time to take the first step with prototyping.