Suitable especially for aerospace and medical applications

Gardigiano (VE) – November 11, 2021 – After months of testing, the R&D team at Weerg – a manufacturing company that offers CNC machining and in-line 3D printing in Italy and abroad – has launched an exclusive new material for additive manufacturing with FDM technology. It is PEEK, an organic thermoplastic polymer with exceptional mechanical properties. A plus that guarantees a performance similar to that of aluminum, making it perfect for metal replacement. PEEK is now available online at weerg.com where, thanks to the versatility of additive manufacturing, it is possible to order 3D prints of complex geometries with an instant quote and delivery in just 3 days.

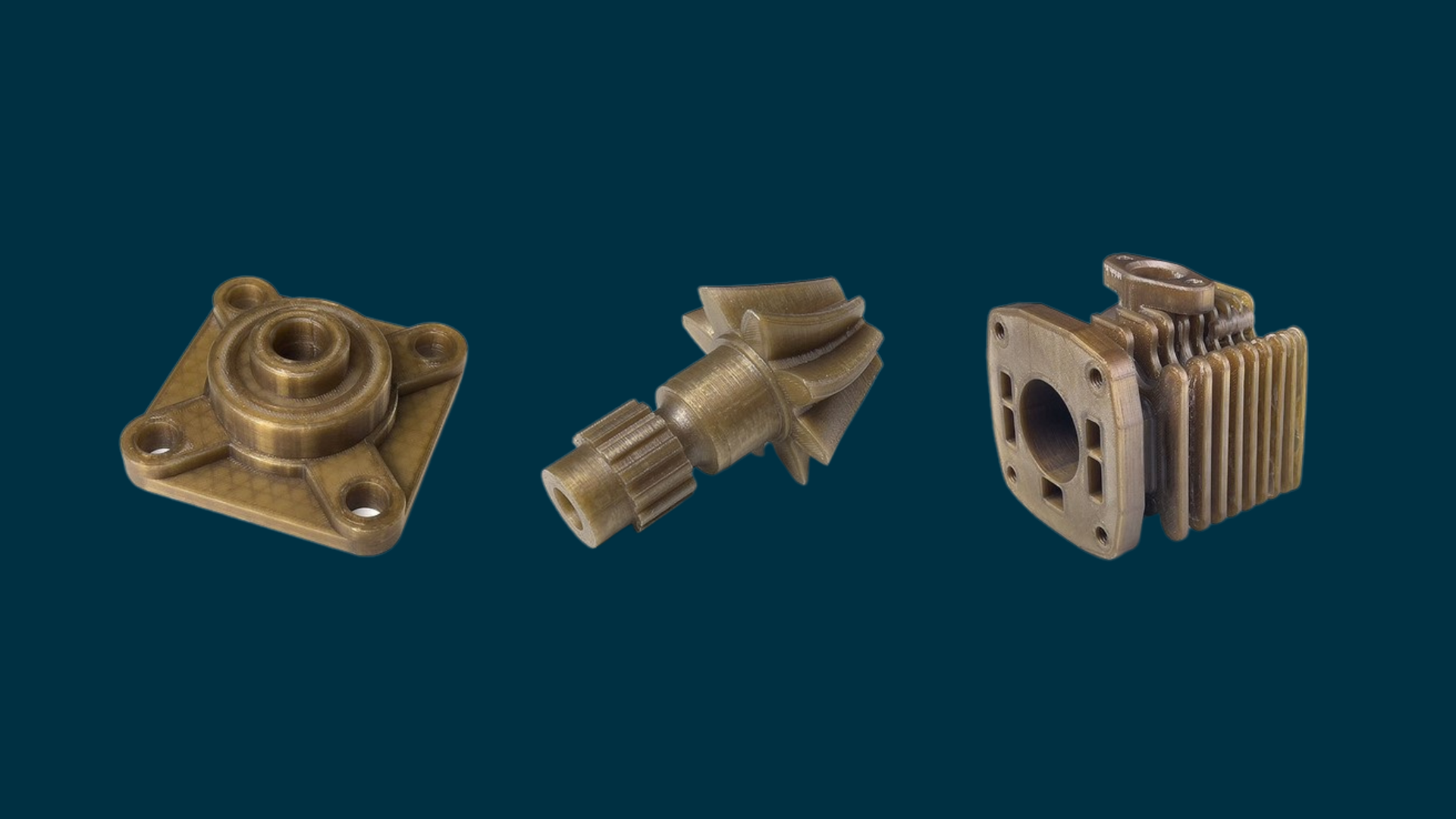

Part of the polyetheretherketone family, this material is often cited as the “king of polymers” due to its unique performance. It is characterized by its extreme light weight while providing a tensile strength (UTS) of up to 89 MPa. Its high mechanical strength and low density make it a formidable candidate to replace the main non-ferrous metal alloys. In addition, the PEEK used by Weerg is flame retardant (tested to UL94 V0 class) and resistant to substances such as oils, greases and hydrocarbons, ensuring excellent thermal performance. In fact, it can withstand continuous use at temperatures up to 145°C and up to 250°C if heat-treated. Other advantages include maximum resistance to vibrations, even the most intense ones, and very low moisture absorption, characteristics that further extend its fields of application. The PEEK tested and used by Weerg is amorphous, with a very particular amber color, to ensure greater ductility and impact resistance. Weerg’s PEEK products are therefore also suitable for use in severe conditions and harsh environments, such as in the aerospace sector, where it can be used for the manufacture of structural components, covers and insulation, or in the medical sector, as it is considered an advanced biomaterial for the manufacture of implants and prostheses.

“In the last year, the 3D printing sector has grown exponentially, which demonstrates the need to design materials that are more and more efficient”, explains Matteo Rigamonti, founder of Weerg. “For this reason, we invest significant resources in the development of materials with special characteristics that can be used for specific industrial applications, constantly expanding our offer”.

Weerg’s proposal, based exclusively on e-commerce, stands out on the international scene for its validity and completeness: 100% made in Italy quality, immediate quotation, competitive prices and reliable delivery date. All this is guaranteed by the excellence of a set of cutting-edge machines equipped with the best technologies. Indeed, the 3D printing department has the largest European installation of HP Multi Jet Fusion 5210 industrial printers, 12 units of which are flanked by the same number of Lherr 4000 (MSLA +4KSPER) stereolithographic printers for resins and 6 additive manufacturing systems with FDM technology. For CNC machining, Weerg has 10 Hermle C42U 5-axis continuous machines divided into two batteries, each of them completely automatized using anthropomorphic robots and loading/unloading stations that communicate directly with the internal management system, as well as 2 fully automatized Mazak Integrex Multitasking i-200 lathes. Cutting-edge solutions for all types of machining, capable of guaranteeing a perfect combination of automation and Industry 4.0 processes.

About

Weerg Srl is an Italian company based in Gardigiano (VE) which, through the weerg.com platform, offers online CNC machining and 3D printing dedicated to different industrial sectors, providing users with all the advantages of a service based exclusively on e-commerce. Advantages of the weerg.com service: real-time online quotation, choice of delivery times and free pre-analysis of the project provided by the customer. Weerg was created in 2015 from an idea of Matteo Rigamonti, founder in 1994 of Pixartprinting SpA, the largest European BtoB web-to-print company. With a consolidated know-how in the world of BtoB e-commerce and in the optimization of customer experience for online shopping, Weerg is able to satisfy orders going from single pieces to mass production. Everything with a quality 100% made in Italy, at competitive costs, in a short time and with the freedom to order at any time of the day. The company targets numerous markets: engineering and mechanical applications, automotive, electronics and aerospace industries, lighting, technology and consumer goods sectors, and medical equipment. Weerg’s production facility is organized according to high levels of automation and uses only cutting-edge machinery to ensure the highest quality.

Contact

Weerg srl

www.weerg.com

PHONE: + 39 041.5383540

EMAIL: info@weerg.com