Laser beam forming greatly boosts quality and production for laser powder bed fusion in additive manufacturing

The combination of a programmable fiber laser that can toggle between single mode and ring mode in a matter of milliseconds plus an optical deflection unit with a zoom axis from RAYLASE is currently revolutionizing additive manufacturing. As demonstrated by research at the Technical University of Munich, the two products solve many of the known problems with laser powder bed fusion (LPBF) in 3D printing – such as a lack of homogeneity in the melt pool and reduced production speed. Thanks to highly dynamic access to a wide range of beam qualities and high-precision beam control, the combination of the two improves quality and production several times over in laser-based and powder bed-based additive manufacturing processes with metals.

The pace of innovation in additive manufacturing is accelerating all the time. The use of cutting-edge laser technology has been part of this trend for years. As a trailblazer in manufacturing, the ring-mode laser has made a name for itself in all things welding. But even more is needed for the LBPF (laser powder bed fusion) process in 3D printing. In this arena, a new laser that can toggle flexibly between single mode and ring mode offers a range of beam qualities from narrow to wide. And it has recently been joined by a new fellow player in the field of laser material processing in additive manufacturing. The way these two lasers work together is so unique and so full of potential that the results are causing something of a sensation in AM.

Prof. Dr.-Ing. Katrin Wudy, expert and professor in laser-based additive manufacturing at the professorship of Laser-Based Additive Manufacturing (LBAM) in the Technical University of Munich (TUM), is currently studying the unique combination of the AFX-1000 fiber laser from nLIGHT and the AM MODULE NEXT GEN optical deflection unit from RAYLASE. Her research focuses on the influence of beam profile on microstructure formation. “We cut apart the workpieces that this process produces, before examining the grain structure in the microsections under the microscope,” says Wudy. “Due to the altered geometries of the melt tracks when using alternative beam profiles, temperature regulation is also changed. We’re seeing different grain sizes and different grain textures in the initial microscopy findings. However, the grain size and texture are essential to the behavior of the components – for example, their ultimate tensile strength or ultimate strain. “So, if we can strategically control grain growth by selecting specific process parameters and beam profiles, the resulting component properties can be fine-tuned – for example, we can make particular parts of a component especially stiff or pliable without any additional post-processing. Properties can also be varied within a single component using sophisticated exposure strategies,” explains Professor Wudy, emphasizing the huge benefits offered by laser beam forming based on a fiber laser and deflection unit.

“The Technical University of Munich, Optoprim – the German distributor of US laser manufacturer nLight, and RAYLASE have joined forces to overcome the critical process limitations of laser LPBF applications – such as lack of homogeneity in the melt pool and reduced production speed,” says Wolfgang Lehmann, Product Manager at RAYLASE, highlighting the benefits of this extraordinary collaboration. With conventional AM processes using a single-mode laser, a range of defects can occur, such as keyhole formation due to overheating, inadequate melt track depth, a powder denudation zone (powder-free zone) around the solidified melt power or balling in the melt pool. These problems are a thing of the past with the product combination comprising the programmable AFX-1000 fiber laser from nLIGHT and the AM MODULE NEXT GEN deflection unit with zoom axis from RAYLASE.

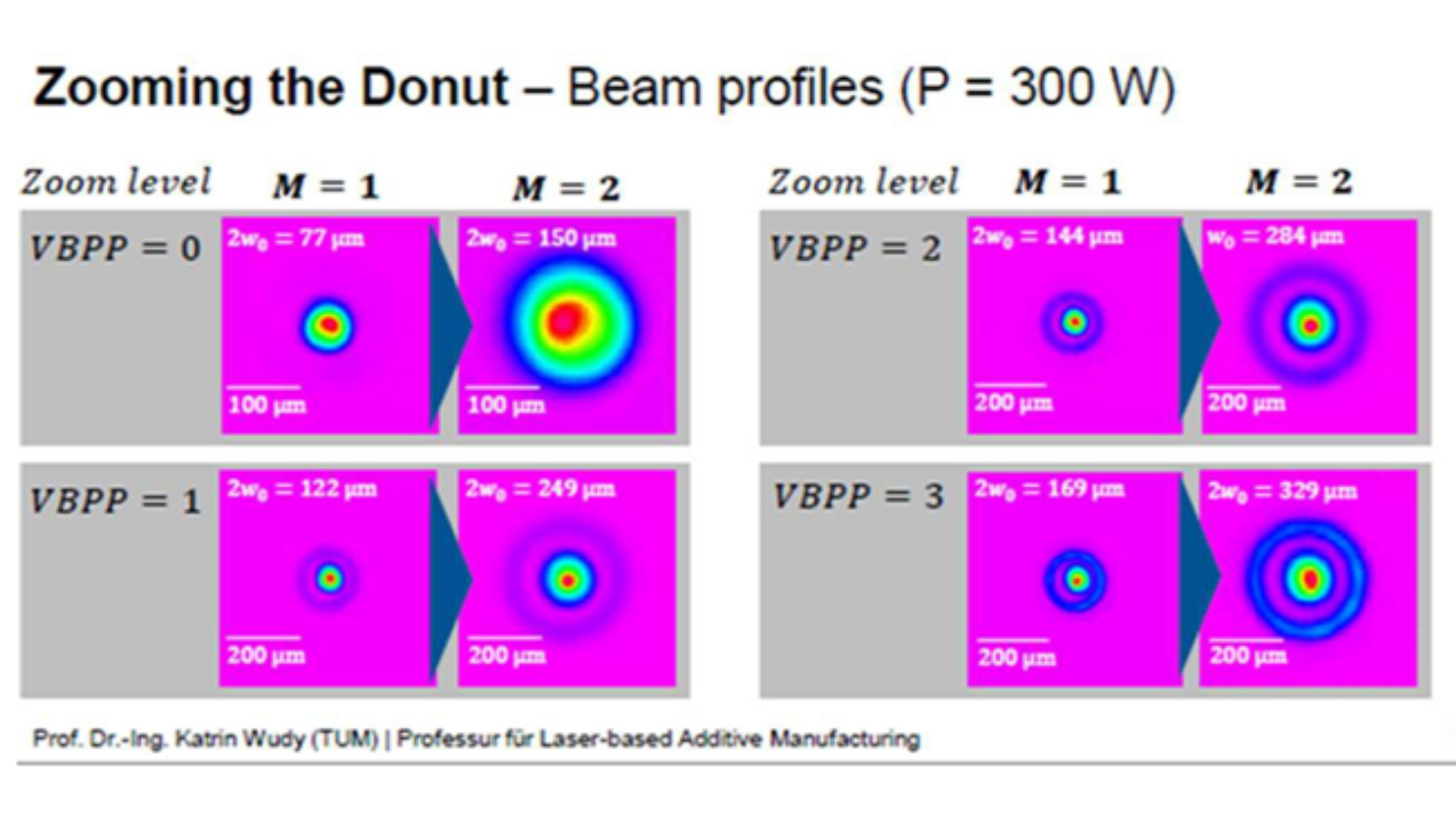

It’s important to note that, with the AFX-1000 fiber laser, the intensity distribution of the beam sources, consisting of a single-mode center and a ring beam, can be switched instantaneously from a typical Gauss profile to six different ring-shaped profiles. The various power outputs of the two overlying laser beams generate an extremely attractive, homogeneous energy input while avoiding spatter and heat cracks. This is crucial for “hatching”, i.e., the movement of the laser in a meander pattern based on the geometries to be exposed in additive manufacturing. The aim here is to build up specific squares on the surface like the squares on a chessboard. The wider the laser beam track, the faster

these can be filled and, in turn, the faster the speed of the component manufacturing process. The edges of the workpiece should be as clean as possible and can be post-processed very effectively with the narrow single-mode beam of the laser’s central fiber. Variable use of single mode and ring mode increases productivity by a factor of around 2.8. If they are used together, however, they are completely unrivalled. The AM MODULE zoom increases the width of the melt track by a factor of 5.5.

The variants are many. While the programmable fiber laser already has a lot to offer, the possibilities are doubled when it is used in combination with the deflection unit’s zoom lens. As Wolfgang Lehmann explains: “We can position the laser tracks with a very high degree of precision depending on the processing field size – to an accuracy of less than 5 µm. The ideal width of the melt tracks depends to a great extent on the grain size of the powder particles. This is normally between 15 µm and 100 µm. Which means that the spot size has to be adapted accordingly. With the AM-MODULE NEXT GEN, the spot diameter can be infinitely adjusted and dynamically doubled during the process. With its highly dynamic deflection mirrors, the deflection unit is capable of deflecting beams around corners at very high speeds. For the hatching process, the deflection unit offers an integrated fiber collimator, a cleverly designed “zoom axis system” for dynamic spot size configuration and numerous process monitoring options for quality control. This ensures consistent spot sizes and power densities at every point in the process field.

In addition to greatly enhancing the AM value chain for the laser powder bed fusion of metals, these innovative products also push the boundaries of serial production as we know it. After all, the ultimate goal of additive manufacturing is to organize the process of constructing a component in a way that is as time-efficient as possible while also maintaining the highest possible quality standards.