ALBUQUERQUE, N.M., March 22, 2022 — X-Bow Launch Systems Inc. (X-Bow), a revolutionary American space technology company focused on 3D printed energetics, announced today that it has exited stealth mode. X-Bow (pronounced “cross-bow”) brings to market its solid fuel rocket motors, along with a suite of small launch vehicles for both orbital and suborbital launch services. Customers already include the U.S. Air Force Research Labs and AFWERX, Los Alamos and Sandia National Labs, as well as the Defense Research Projects Agency (DARPA).

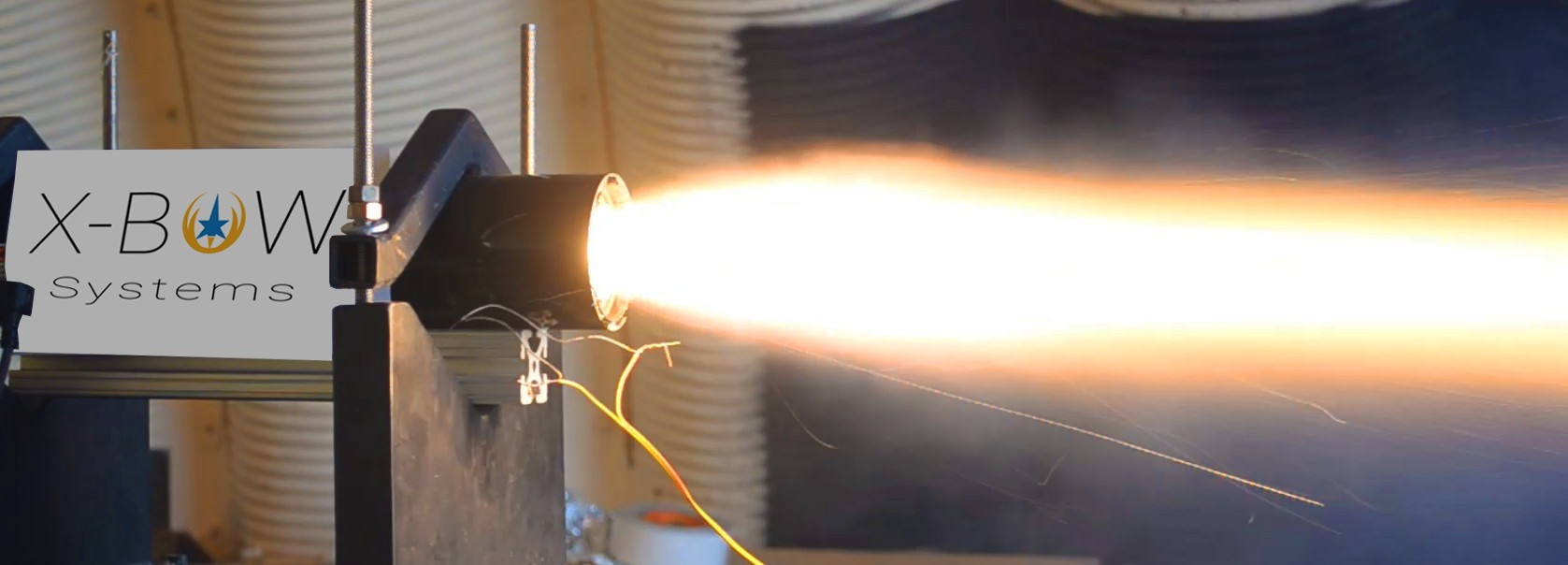

Since its founding in 2016, X-Bow has focused on the design and development of 3D printed solid rocket motors that are more efficient and considerably more cost effective than traditional motors. X-Bow’s new class of highly flexible, reliable and ultra-responsive solid rocket motors introduces new products to a market that has not seen significant technological change for decades.

“X-Bow is leveraging a unique combination of technologies with an improved manufacturing model to serve existing aerospace markets and enable new ones. Our breakthrough 3D printing technology is positioned to rapidly innovate the solid propulsion and energetics markets just as SpaceX revolutionized the launch market. Our mission is to modernize solid motor production through additive manufacturing while dramatically improving unit economics” said JASON HUNDLEY, CEO.

The company’s product line includes propellants, motors, and turnkey launch services that are available to both government and commercial space customers. Staffed with veteran aerospace professionals, the company is excited to be growing with over 60 employees strategically located across the country.

“For too long, aerospace markets have lacked a 21st century solution that utilizes cutting edge technological advances such as 3D printing, digital engineering techniques and automation. X-Bow is well positioned to fill the gap with disruptive technology that can shake up the emerging space economy” said MATT BIGGE of CROSSLINK CAPITAL who has been a key investor in the company. “We are confident in the experienced team at X-Bow and thrilled to be supporting its mission. This company is poised to revolutionize the future of solid rocket motors.”