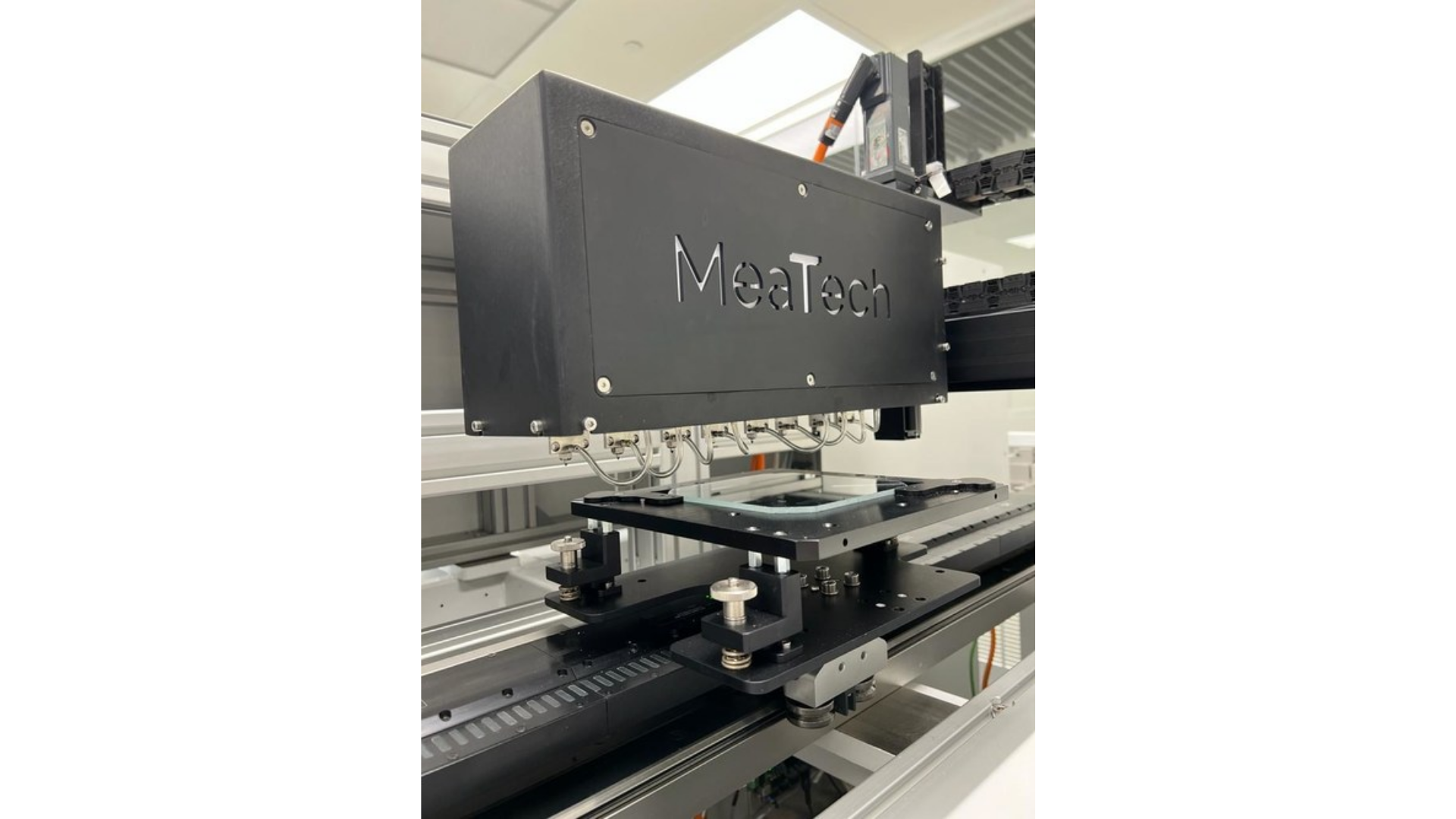

REHOVOT, Israel, April 28, 2022 — MeaTech 3D Ltd. announced a unique multiple-nozzle modular printing head developed in house. The new technology can produce complex meat products with pinpoint precision at an industrial rate of production without impacting cell viability. It is a breakthrough toward the mass production of cultured meat using cells and bio-materials.

MeaTech’s new modular bioprinting design allows flexibility with up to hundreds of nozzles and multiple bio inks with low- and high-viscosity. MeaTech’s software gives manufacturers complete digital control to produce a wide variety of cultured meat products based on any desired complex 3D models.

MeaTech’s private subsidiary, based in the Rehovot Science Park, the epicenter of Israel’s food-tech industry, is focused exclusively on developing and commercializing MeaTech’s 3D-printing capabilities in-house and to third parties in the food tech sector. This will allow MeaTech to expand and accelerate the company’s path toward market entry and address a lack of broader technology infrastructure in the cultured meat industry for customized mass production.

Arik Kaufman, CEO of MeaTech: “We are excited to capitalize on this technological achievement which we believe, through our private subsidiary, will speed up MeaTech’s entry into the market as the leading supplier of advanced cultured meat bioprinting technology and services to third-party food-sector players.”