Leipzig, Germany, August 4, 2022 – BellaSeno GmbH announced the start of two clinical trials of its resorbable scaffolds using additive manufacturing technologies in Australia. Sponsored by its Australian subsidiary BellaSeno Pty. Already, recruiting has started in Brisbane, Australia.

The first trial is expected to enroll 10 patients with pectus excavatum, a common congenital chest wall deformity in which the breastbone is sunken into the chest. Principal investigator of this trial is Dr. Michael Wagels, Director of the Herston Biofabrication Institute (HBI), Specialist Plastic and Reconstructive Surgeon at the Princess Alexandra Hospital, Director of the Australian Centre for Complex Integrated Surgical Solutions (ACCISS) and Senior Lecturer at the University of Queensland. BellaSeno already published first-in-human data in 2021, demonstrating that its implant was able to camouflage a pectus excavatum defect not reconstructable by conventional techniques.

The second trial aims to enroll 20 patients who either need breast implant revision or surgery to correct congenital breast defects. Principal investigator of the second trial is Prof. Owen Ung, Director of the Comprehensive Breast Cancer Institute (CBCI), consultant breast surgeon at the Royal Brisbane and Women’s Hospital and Professor of Surgery, University of Queensland, Australia.

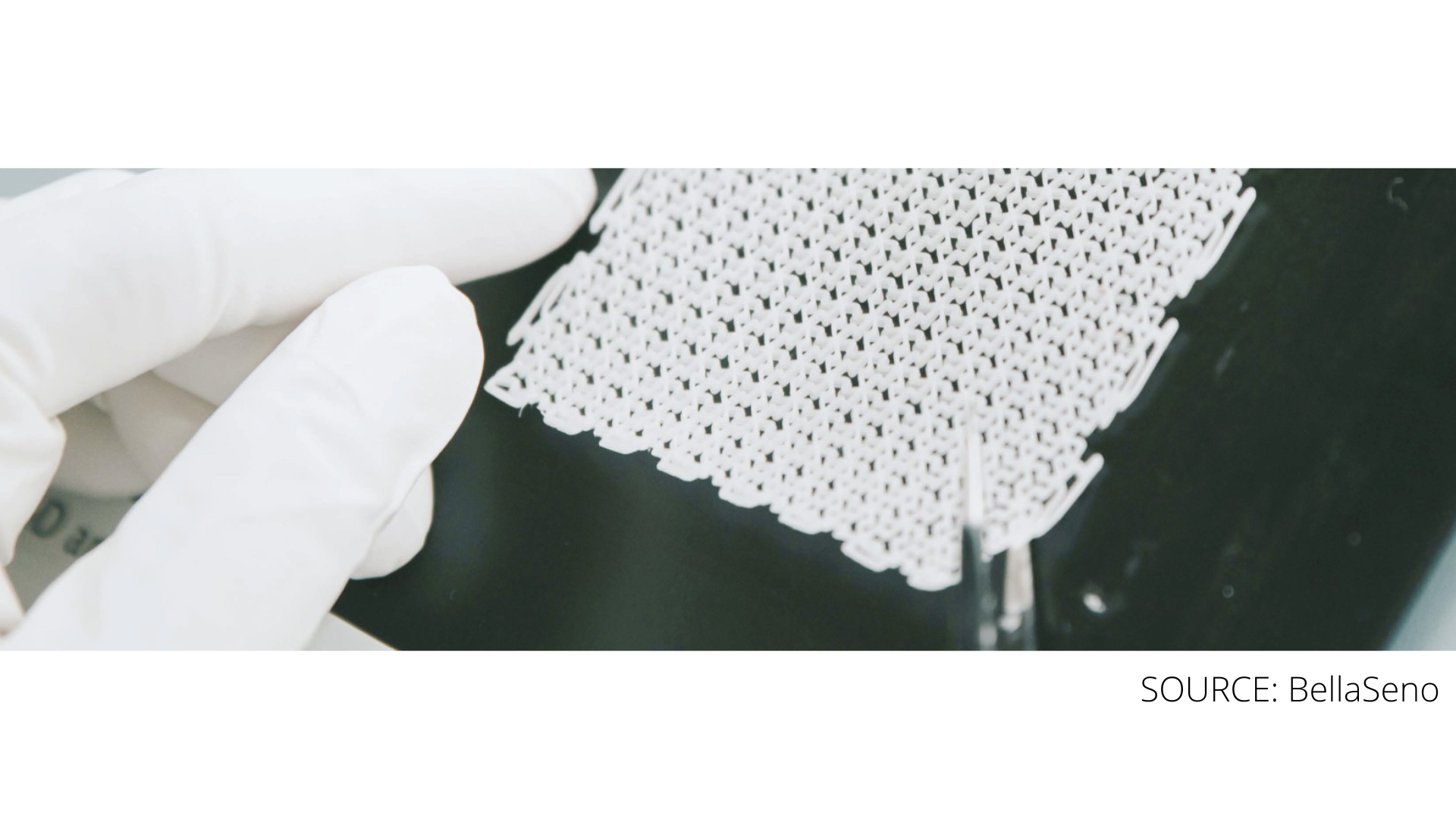

In both trials, patients will receive porous polycaprolactone implants produced in Bellaseno’s AI-driven additive manufacturing facilities by a no-touch approach. Polycaprolactone has been used in healthcare for decades as absorbable suture material. Once the implants are inserted in compressed form by minimal invasive surgery, the structure unfolds and is subsequently grafted with the patient’s own fat tissue obtained by liposuction. Within up to 5 years, the polycaprolactone scaffold is fully absorbed and replaced by fat cells, leaving no permanent remnants of foreign material in the body. This scaffold-guided tissue reconstruction (SGTR) provides a promising alternative to silicone or other permanent implants. The Company´s novel implants are designed to ultimately result in natural tissue.

Primary outcome of the trials will be intra- and post-operative device safety; secondary endpoints are adverse event rate and frequency of complication. Secondary endpoints comprise, among others, change in (fat) volume and soft tissue retention as well as pain and quality of life.

“This trial is a very important step for us to demonstrate that our approach is not only safe, but leads to substantial improvements in terms of long-term safety, health and quality of life,” said Dr. med. Tobias Grossner, CMO of BellaSeno. “We very much hope the trials once more confirm our scaffold-guided tissue reconstruction concept.”

“We are delighted to spearhead the administration of novel, fully absorbable implants for soft tissue reconstruction applications. There is a clear need for a safe alternative to contemporary alloplastic materials and operative techniques in pectus excavatum and breast surgery. Having customizable implants that resorb, leaving behind the patient’s own tissues, is a big step forward,” said Dr. Michael Wagels, Principal investigator of the pectus excavatum trial.

“It is important to us that patients have access to healthier alternatives to permanent implants. There is a strong demand for restoring fully natural breast tissue without potentially risky remnants in the body. We believe that BellaSeno´s solutions can play an important role in addressing these needs,” added Prof. Owen Ung, Principal investigator of the breast trial.

About BellaSeno: BellaSeno GmbH was founded in 2015 and is headquartered on the BioCity campus in Leipzig, Germany, with a subsidiary in Brisbane, Australia. The Company is developing novel resorbable soft tissue and bone reconstruction implants made by additive manufacturing (3D-printing) under ISO 13485 certification. The Company has received substantial financial support from private investors as well as from the Saxony Development Bank (SAB), the European Fund for Regional Development (EFRE), Germany´s Federal Ministry of Education and Research (BMBF) and the Australian government. The Company is thereby co-funded from tax resources based on the budget adopted by the members of Saxon State Parliament.

About Senella®: Senella® is a patented porous scaffold made of resorbable Polycaprolactone (PCL) containing highly-specialized topological and design features, which act as recipients for injected fat tissue isolated with a standard liposuction procedure. The implant is designed to get absorbed over a span of up to 5 years and to provide a stable platform for the injected fat tissue to mature, adapt to its environment and stabilize. The clinical end result is a natural soft tissue – without remnants of foreign material. Senella® therefore has the potential to alleviate the complications found in current breast reconstruction and augmentation approaches.