SALT LAKE CITY, Sept. 27, 2022 — SINTX Technologies, Inc. announced the receipt of a Phase II award of $1.1M, issued by the U.S. Department of Energy (DOE) to develop, design and characterize 3D-printed alumina ceramic heat exchangers for heating, ventilation, and air conditioning systems (HVAC). The proposal was originally submitted by Technology Assessment and Transfer (TA&T), now a wholly owned subsidiary of SINTX. The Phase II award follows the successful completion of the Phase I effort by TA&T. The award aligns with the DOE’s interest in supporting unique technologies for next-generation non-metallic heat exchanger systems to improve the energy efficiency of heat pumps and air conditioners over a broad range of operating conditions for building and industrial applications.

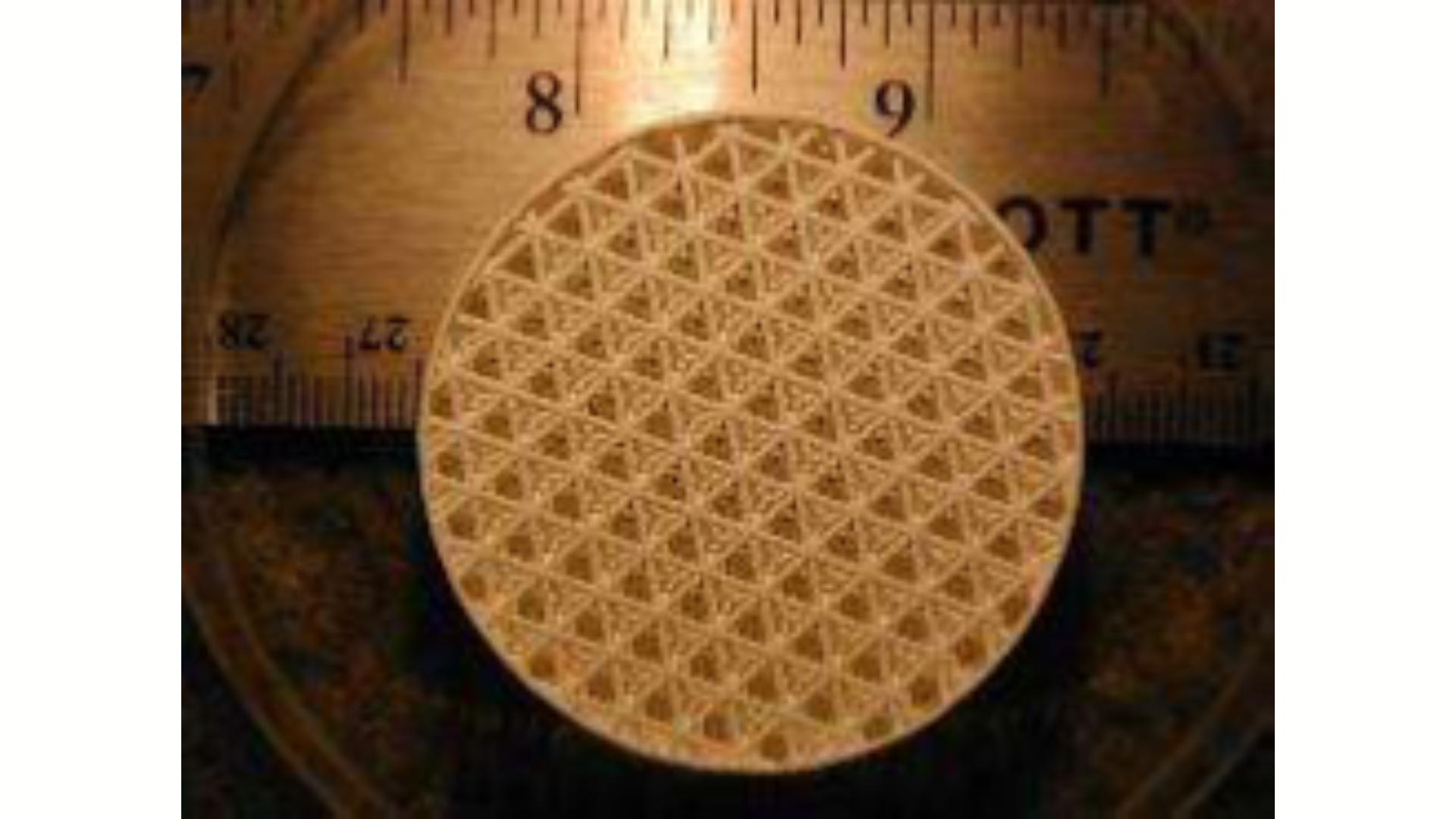

Non-metallic alumina ceramic heat exchangers offer lighter weight, exceptional corrosion resistance, and higher thermal conductivity than stainless steel and/or polymeric heat exchangers. 3D printing enables fabrication of compact micro-heat exchangers with higher heat transfer and leakage-free features that cannot be achieved with conventional metal heat exchanger fabrication methods.

“In order to meet the objectives of the original Phase I effort, SINTX – in collaboration with the University of Cincinnati and industrial partner Carrier – proposed the development, demonstration and potential commercialization of highly efficient, light weight, compact additive manufactured (AM) alumina ceramic heat exchangers for a broad spectrum of residential and industrial air to refrigerant HVAC applications.,” said Dr. Larry Fehrenbacher, Vice President of Technology, SINTX Technologies. “We believe that this concept has strong merit, and this new Phase II award will allow SINTX to advance the technology towards scale-up and commercialization.”

TA&T, recently acquired by SINTX, initiated development of 3D printing of Ceramics in 1997 and has developed the capabilities to fabricate parts in various ceramic materials such as alumina, silica, yttria stabilized zirconia and transparent magnesium aluminate spinel. Today SINTX provides commercial prototyping and manufacturing services making high purity ceramic parts using 3D printing. Several manufacturers of electro-surgical instruments use TA&T’s fabrication service extensively for prototyping and low-rate initial production.

The content included in this release is solely the responsibility of the authors and does not necessarily represent the official views of the Department of Energy.