SAN FRANCISCO, CA, October 17, 2022 — 3DPrinterOS‘ cloud solution is now available with the new Formlabs integration for print farms of any size to help scale your additive manufacturing operations.

There’s a lot of talk about “the cloud” and the benefits its use brings to digital manufacturing. Just like so much that’s been overhyped and oversold when it comes to all things additive manufacturing (AM), though, “the cloud” is often a misnomer.

Too many companies position their software offering as a “cloud-based solution” when all it means in practice for them is downloading from their website with maybe, maybe an option to network locally and share files.

Rather than requiring a dozen proprietary slicers that have to be individually downloaded and take up valuable memory and computing power – and thus tied to only that individual console – true cloud operability means something much more impactful.

A neutral, fully cloud-supported slicing capability removes workflow bottlenecks and potential security holes for users looking to bring in new hardware and materials capabilities to their 3D printing operations. Perhaps most meaningfully, realizable cloud support can power print farms.

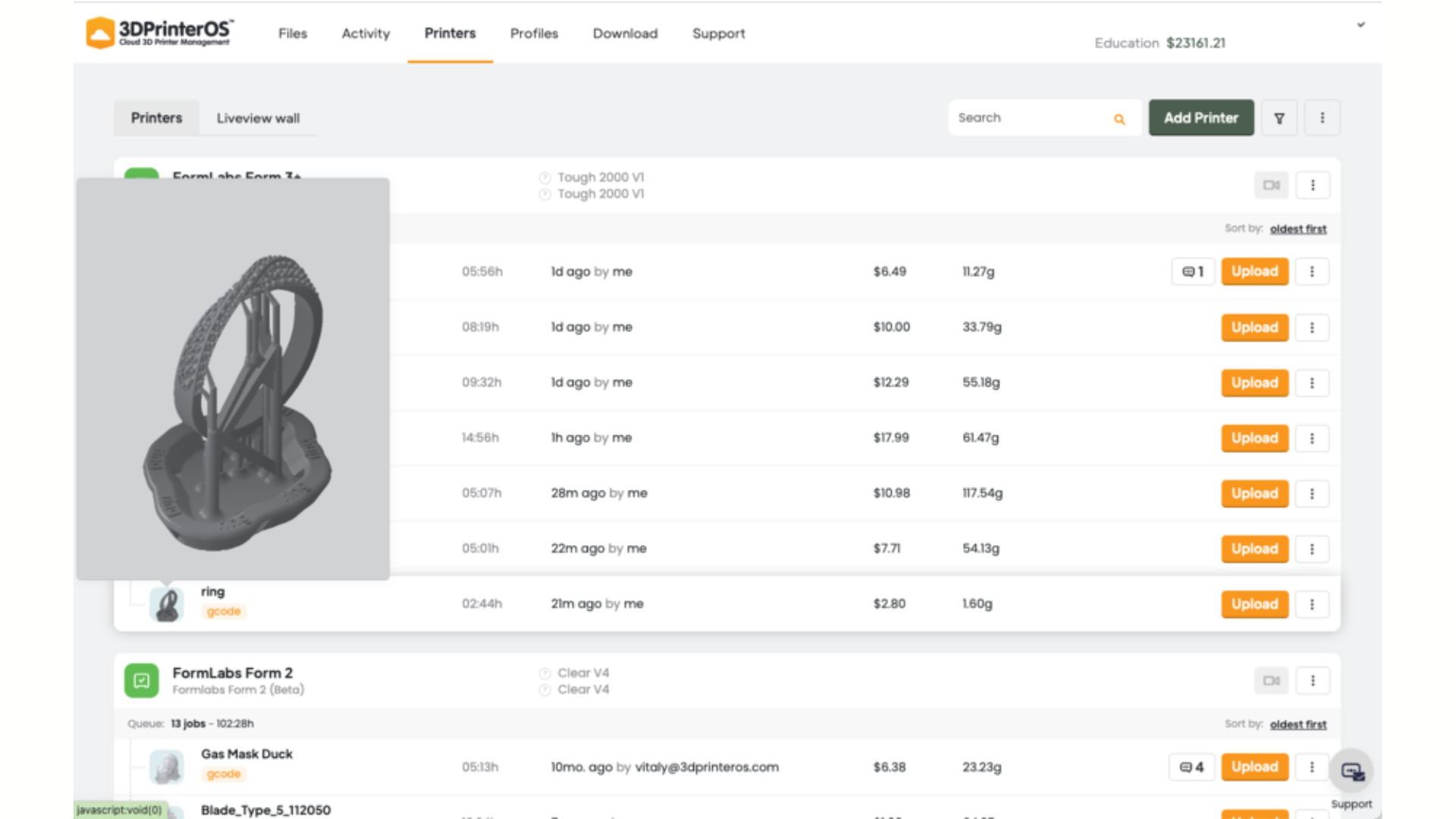

For over five years, Formlabs in-cloud slicing has been a much demanded feature from the 3DPrinterOS users. We are extremely excited and proud to finally offer the community one-click print for Formlabs 3D printers, straight from the web browser, with no downloads.

Simply upload your part, and it’s instantly sliced in the cloud or private servers, ready to print and scale across an infinite number of users, printers, and locations,” said John Dogru, Founder, 3D Control Systems.

3DPrinterOS: The first operating system for desktop 3D printers, 3DPrinterOS, brings ease-of-use to a fragmented market. We support any 3D printer, bringing know-how and neutrality to create a world’s-first offering of integration and secure operation.

Our decentralized platform has been used to build more than 2,000,000 parts in more than 130 countries, with almost a millennia of total 3D printing time.

We work with some of the biggest names in the 3D printing industry, from hardware OEMs to software developers, to offer the single most important outcome for users: solutions.

3DPrinterOS, bringing unity to the industry, offers one platform that allows you to slice natively, replacing the OEM’s software, and help scale your additive manufacturing operations.

Unlike most other end-to-end solutions on the market, 3DPrinterOS doesn’t require you to ever leave the platform to bounce between software suites.

“Our customers, and the industry, have been waiting for cloud slicing for the Formlabs printers. Very similar to the rest of the industry, until now you’ve had to use desktop software to prepare everything.

It’s not easy, you can’t give the ability for thousands of users in a university or enterprise to securely and easily send jobs to the 3D printers, with one click.

That’s why 3DPrinterOS exists, and why we are the #1 choice for the top hundred universities in the world like MIT, Harvard, Yale, etc, and top companies like Bosch, Google, John Deere, Eaton etc.,” said Dogru about the integration.

“Our powerful proprietary cloud technology allows us to house all the slicers, on a server, and instantly give your users access to send print jobs without having to download all the manufacturers software on your desktop and go through a complex learning curve.”

Supported systems include the best of the Formlabs portfolio, encompassing the Formlabs Form 2, Form 3+, Form 3L, Form 3B, Form 3BL, and Fuse 1.

The Formlabs slicer, available now with full cloud slicing, is a significant stride forward for both the hardware OEM and 3DPrinterOS. It’s also a direct response to what customers have been requesting. Powerful, neutral operability is set to push the boundaries of what Formlabs operators can achieve.