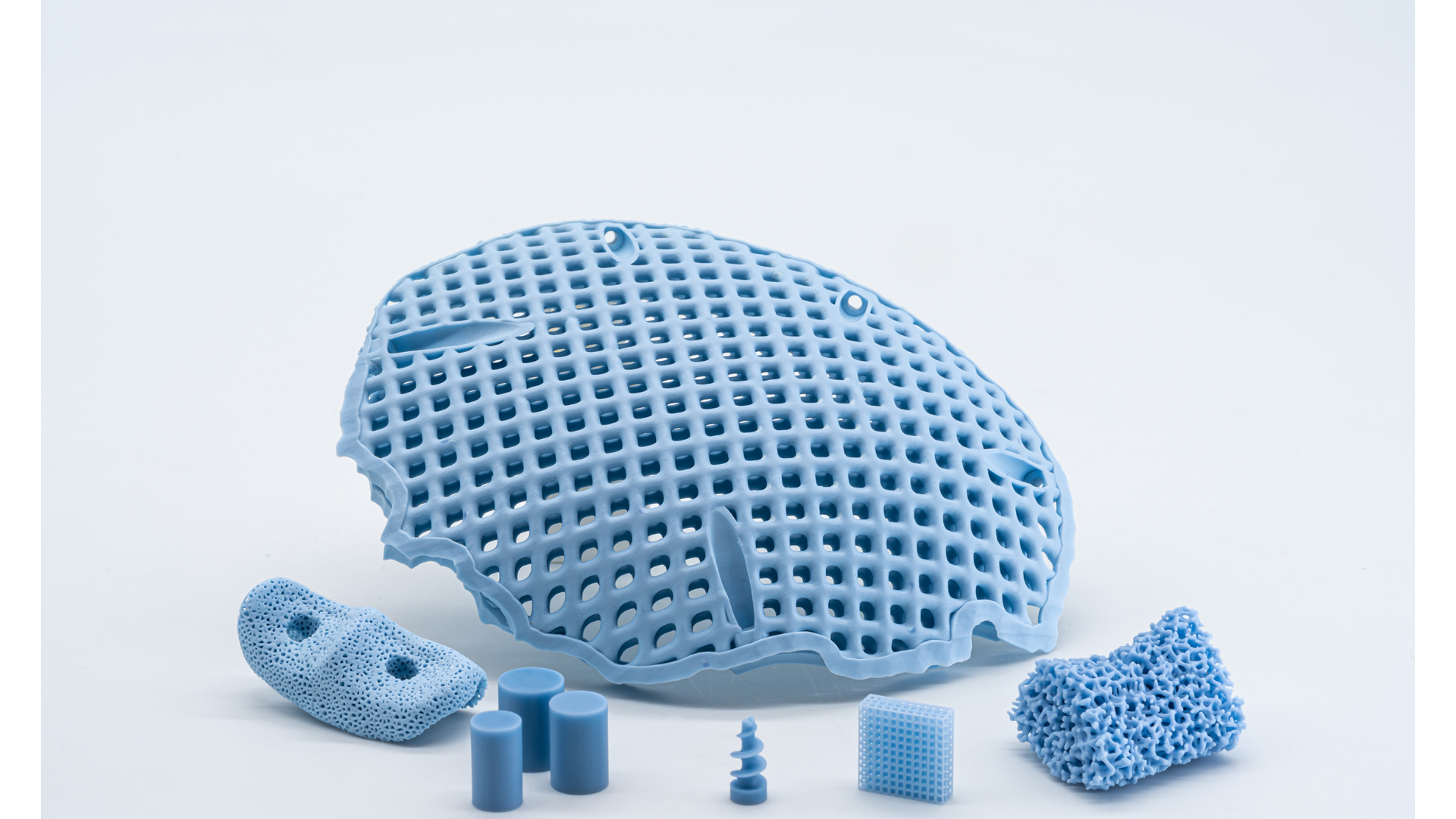

Vienna, Austria/November 29, 2022 — Through intensive cooperation with users of their previous bone substitute materials for ceramic 3D printing, Lithoz has developed the new LithaBone HA 480. With the goal to make the material more economically viable and the use of 3D printing for bone replacements even more effective, the greatly improved human bone-like ceramic material had a great reception from expert visitors at its world premiere at Formnext, where the distinctly blue complex parts on show were of particular interest.

In medicine, ceramics are considered ideal materials for devices and implants due to their biocompatibility, low thermal conductivity, and lighter intrinsic weight. Most importantly, however, certain ceramics can be resorbed by the body, eliminating the risks connected to second surgeries. The wide range of bone structures in the body necessitate that ceramic materials for bone replacement fully cover this range and are biocompatible and resorbable. The planned interaction of the bone substitute material with adjacent bone and tissues depends on the optimized design of geometries which – accordingly – determines clinical success, as bone regrows along the material’s guide structures and the ceramic dissolves in the body.

Lithoz’s new ceramic bone replacement material LithaBone HA 480 offers several major improvements, including:

- Significantly higher wall thicknesses – a key requirement for versatility reasons. With LithaBone HA 480, previous maximum wall thicknesses of <1.6mm (LithaBone HA 400) have been increased to 10mm, while minimum wall thicknesses required have been reduced even further, significantly broadening the range of applications.

- More precise imaging accuracy of fine structures – in line with the strengths of LCM, one clear goal was to offer a higher level of ultra-precise resolutions and highly complex structures when working with hydroxyapatite. LithaBone HA 480 shows strongly reduced overpolymerization with a simultaneously improved depth of cure, resulting in a simpler selection of build parameters and a significantly more stable manufacturing process.

- Ten-fold longer shelf life – eliminates the obstacle of previous materials’ short shelf life impacting on availability required for urgent surgical interventions.

- Parts are significantly easier to clean, making up valuable time during often vital medical interventions. Experienced users have confirmed significantly faster and easier cleaning processes thanks to an improved binder composition.

KLS Martin, a pioneering German company in medical technology, has been a highly important user of 3D-printed bone substitute implants since 2015. LithaBone HA 480 and the specification of the development goals were ultimately a direct outcome of invaluable customer feedback from this collaboration. At KLS Martin, the new Lithoz material instantly made a strong impression: ”We at KLS have been producing CMF implants for human use on our Lithoz CeraFab printer since 2015, with excellent results in terms of accuracy of fit, tolerability and healing success. We already have had the chance to work with HA 480 and the results are outstanding: from mechanical properties over higher wall thickness to size and lattice structures, LithaBone HA 480 has convinced us of a considerable improvement compared to its predecessor.” – Adem Aksu (Director Development Biomaterials at KLS)