WEST LAFAYETTE, Ind./November 29, 2022 – Purdue University researchers have developed a patent-pending method to add particles to filament and disperse them evenly through a traditional fused deposition modeling, or FDM, 3D printer, which will aid industry in manufacturing functional parts.

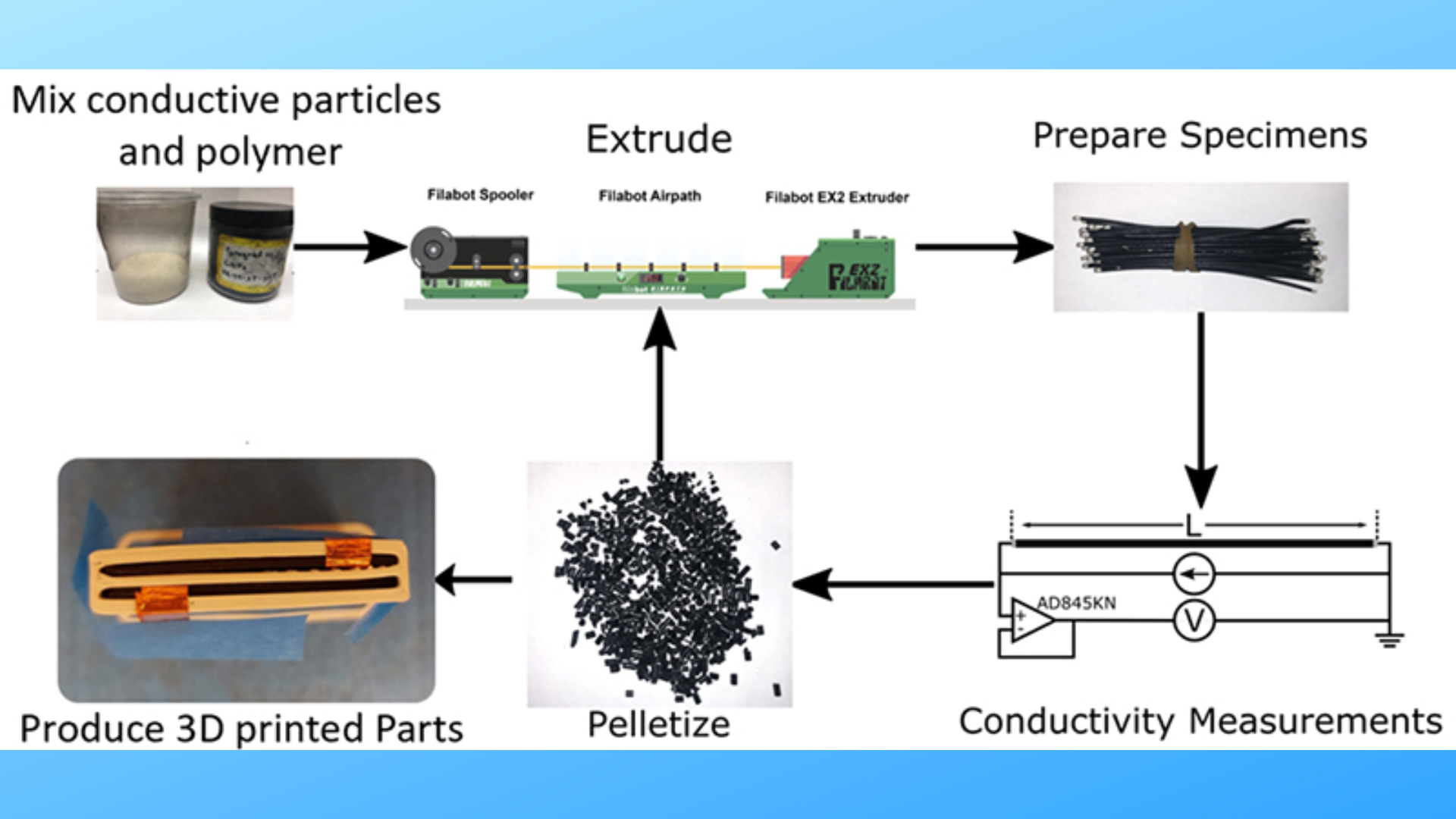

Brittany Newell and Jose M. Garcia-Bravo, associate professors in the School of Engineering Technology in the Purdue Polytechnic Institute, and Tyler Tallman, assistant professor in the School of Aeronautics and Astronautics in the College of Engineering, have created a novel wet-mixing method to introduce electrically conductive particles into 3D printing filament polymers. Cole Maynard, who earned his PhD in August, and Julio Hernandez, a doctoral candidate, were pivotal to the research.

Traditional 3D printing makes prototypes of parts with no sensing capabilities. Sensors must be added to the part after the fact if assessments are to be made. The process can be thought of as adding sprinkles to cookies after they are baked: The sprinkles exist only on the outside of the cookie. Traditional foil-type strain gauges, which are the most common strain sensors, are adhered to the surface of a printed part by an epoxy resin, Newell said. However, in this work the sprinkles are added throughout the cookie dough before baking. This means that sensing capabilities are an inherent part of the printed component and allow for sensing inside of the component. Unlike sprinkles, these sensors are too small to be seen without a microscope. Their tiny scale allows the printed part to maintain strength it would have otherwise sacrificed due to large sensors built in, while still achieving fully integrated sensing capabilities.

“Generally, we apply that strain gauge across the full part or apply it to the top and bottom of the part to get information on overall strain across the part,” Newell said. “However, the middle and internal structures are never monitored since the gauges are glued to the surface.”

The Purdue wet-mixing method ensures an even distribution of particles throughout the filament. With the sensors dispersed evenly in the filament, manufacturers and researchers can design parts with a wider variety of shapes.

“The results from this work enable users to create complex 3D structures with embedded strain gauges, rapidly moving traditional prototype pieces into fully functional and structurally assessable parts,” Newell said. “A limitation of application of 3D printed parts has been in their durability. With this development, we can continually monitor the structural health of the part with the sensor embedded in the print.”

Tallman said, “This method produces materials that are conductive with very good uniformity, which greatly expands the electrical applications of 3D printed parts and sensor designs.”

Garcia-Bravo said, “The materials are also tunable, meaning we can adjust the electrical and mechanical properties to optimize the sensor or part for a desired application.”

The novel wet-mixing process is not limited only to sensor conductivity.

“This work can be further expanded to add other particle types using the same wet-mixing method,” Newell said. “This could include the addition of magnetic particles for electromagnetic fields, fluorescent particles and other functionalities.”

The research was published in the July 2022 edition of the peer-reviewed journal Advanced Engineering Materials and in the 2020, 2021 and 2022 editions of the journal American Society of Mechanical Engineers Smart Materials, Adaptive Structures and Intelligent Systems. The researchers have received funding from the Naval Engineering Education Consortium, or NEEC, a program from the NAVSEA warfare centers aiming to cultivate partnerships between the Navy and higher education institutions.

The researchers disclosed the innovation to the Purdue Research Foundation Office of Technology Commercialization, which has applied for a patent on the intellectual property.