TEL AVIV, Israel and MILAN/ December 7, 2022 — Balena announced the debut of its eco-chic BioCir Slides, made of its proprietary, 100% biodegradable plastic – developed to help the fashion industry put an end to unsustainable amounts of plastic waste and kickstart biodegradable plastic use in shoes and other clothing. Balena’s BioCir™, the first fully moldable, biodegradable elastomer, provides a viable alternative to the polluting plastic materials currently used by fashion brands for clothing and footwear.

Balena’s proprietary BioCir™ 100% compostable plastic is durable, flexible, soft, and smooth, which makes it the perfect alternative to current polluting shoe materials while allowing brands to develop footwear identical in look and feel to their current products. The biodegradable material can be treated like any other and used in regular injection molding processes as well as 3D printing, with the limitless manufacturing opportunities that these afford. It can be integrated into regular manufacturing processes with ease and replicated at scale globally, reducing a significant barrier to entry for manufacturers. Balena’s groundbreaking slides are the ultimate proof-of-concept demonstrating the durability, utility, and comfort of BioCirTM.

To demonstrate the exciting potential of this unique technology, Balena has debuted its fully compostable slides for both men and women, designed and manufactured in Italy and made entirely of BioCir, by dropping the first thousand pairs in the company’s hometown, Tel Aviv. These BioCir Slides – colored and scented using natural cinnamon – are already being worn by fans of fashion and comfort throughout the city, putting their feet first towards a greener future.

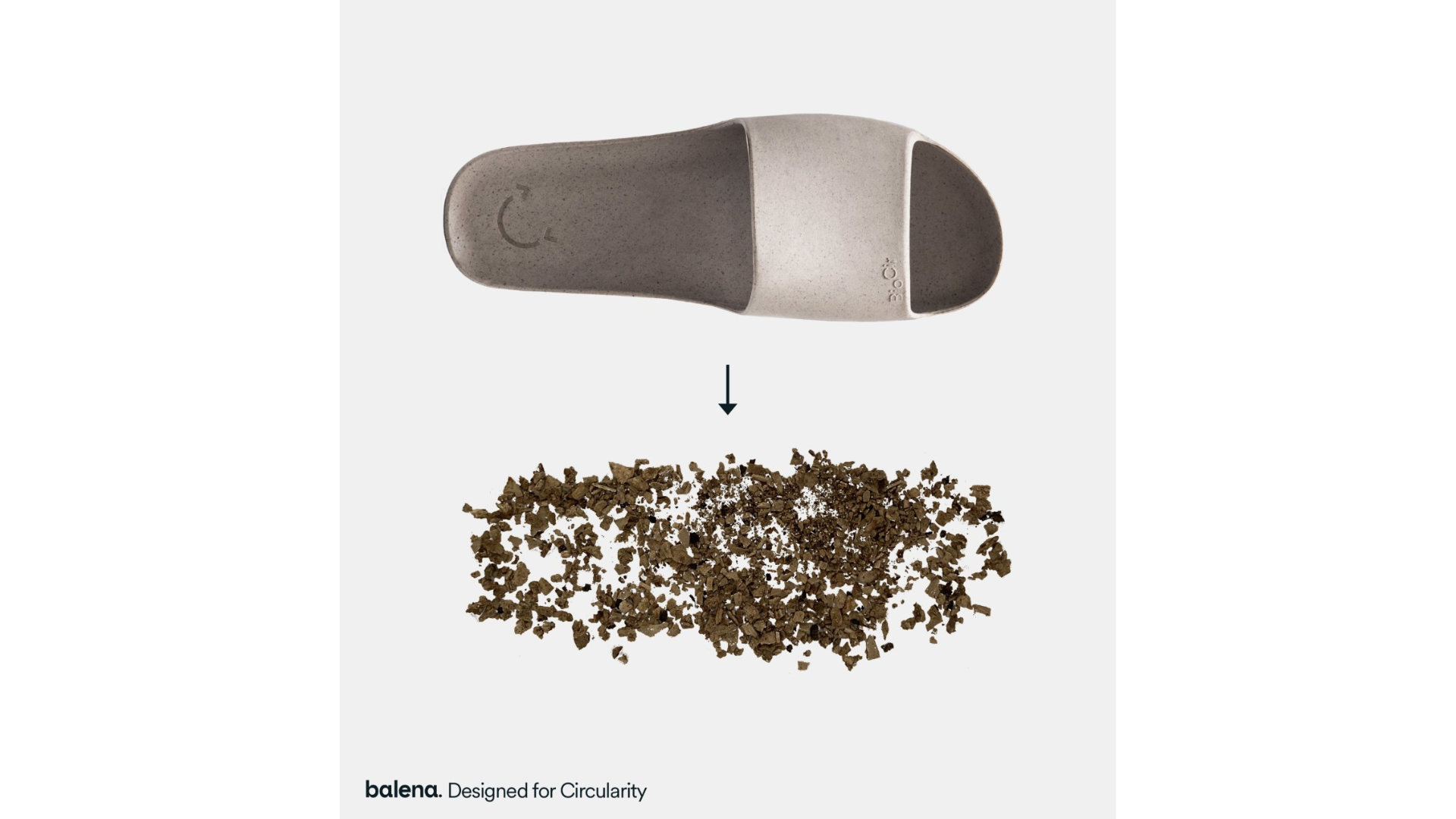

As part of the debut, Balena has also introduced a fully circular system – BioCycling™ – that facilitates the disposal and complete biodegradation of its BioCir slides in an industrial compost environment. Once a customer has finished using the slides, instead of tossing them into the garbage on their way to a landfill, they can instead return them to designated take-back spots throughout the city where they are collected for full biodegradation at a local industrial compost facility. This model, aimed at reducing fashion’s contribution to plastic waste, can be replicated around the world.

The world’s addiction to fast fashion has resulted in staggering volumes of clothing and footwear waste generated each year – an estimated 92 million tons of textile waste is created annually worldwide and just 12% of the material used for clothing is recycled. Balena is on a mission to change this by creating a fully circular model that relies on the power of composting to lower fashion’s footprint on the global environment.

“The global fashion industry is one of the world’s biggest polluters. At Balena, our goal is to help turn this around,” said David Roubach, Founder and CEO of Balena. “We’re doing this by creating our own viable biodegradable plastic alternatives and fully circular systems that can be easily scaled, and copied and pasted across the globe. We hope our BioCir footwear shows the world that there is a real alternative: Fashion can be fabulous, functional and Earth-friendly. We’re proud to be the company opening the door for any fashion brand to start stepping into a more circular future.”