BOSTON/December 6, 2022 — Desktop Metal announced the company has installed more than 1,100 3D printing systems for metal components worldwide.

More than 80% of installed systems worldwide are direct metal 3D printing systems. Among sand 3D printing systems, which are used for the final production of digital metal castings, more than half of the installed systems are now located at multi-system sites dedicated to high-throughput mass production applications. A significant number of metal binder jet systems are also being used to print technical ceramics, most often silicon carbide.

“As the highest throughput process in 3D printing, binder jetting is the additive manufacturing technology that will truly take the industry into mass production at high volumes,” said Ric Fulop, Founder and CEO of Desktop Metal. “Our 3D printing systems are already being used to manufacture powertrain components, automotive interiors, oil and gas, food processing equipment, hydraulics and some of the most advanced aerospace and nuclear parts.”

Binder Jet is a Differentiated AM Solution: Binder jet 3D printing is one of seven additive manufacturing processes recognized by ASTM. The process transforms virtually any powdered materials — metal, sand or ceramic — into functional precision parts and tools at high speeds. An industrial printhead selectively deposits a binder into a bed of powder particles creating a solid part one thin layer at a time, just like printing on sheets of paper. The technology is viewed as a desirable and sustainable production method, largely because of its high speed, low waste and cost, as well as material flexibility.

Desktop Metal offers the world’s leading portfolio of binder jet 3D printing systems, backed by the most experienced binder jet team in the industry. In addition to Desktop Metal’s binder jet systems for production of metal and ceramics, the company’s ExOne brand offers world-leading sand binder jet systems for digital metal casting, and the company’s Forust brand offers turnkey binder jet printing of upcycled wood waste.

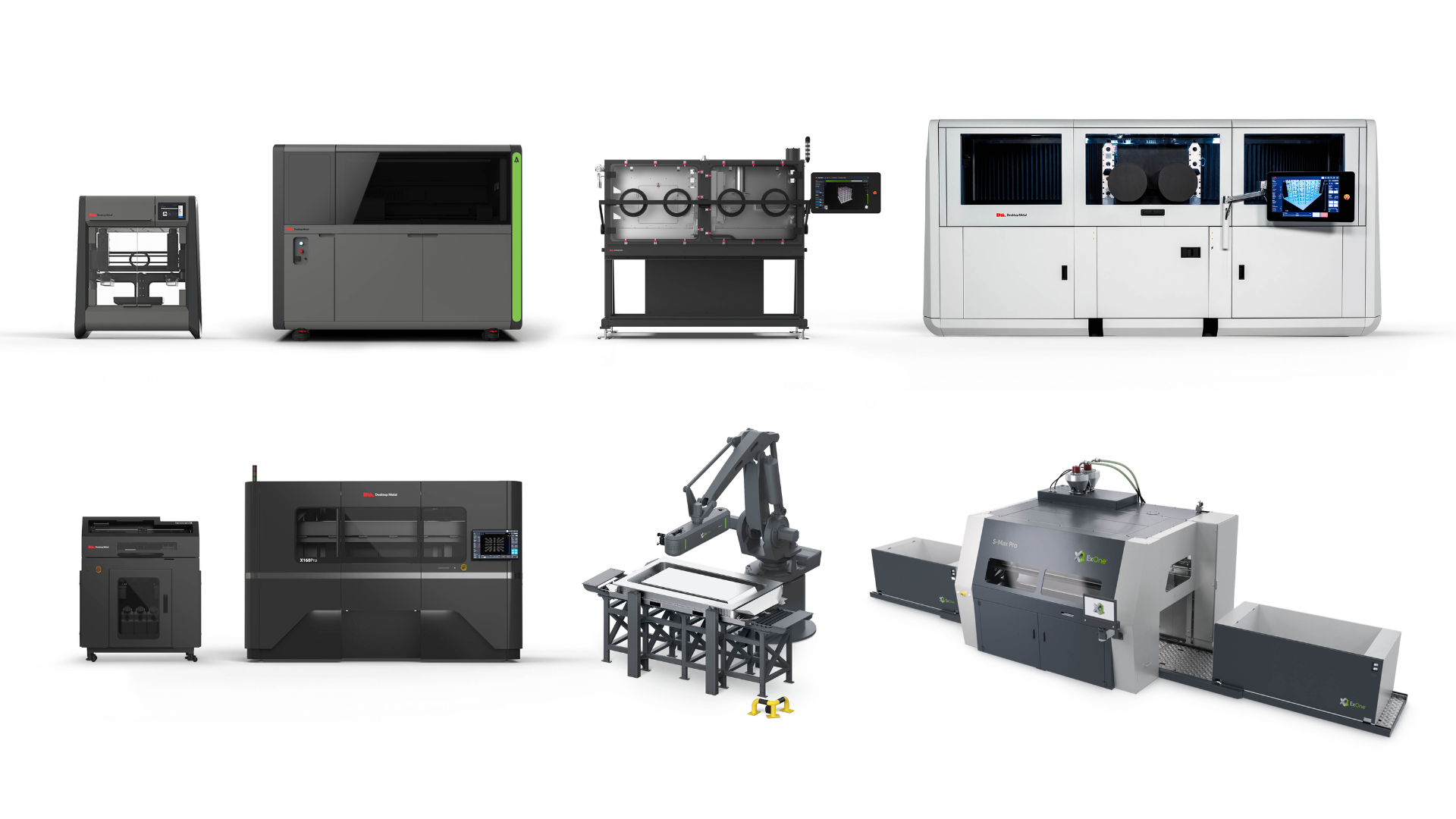

The company’s portfolio offers the widest selection of mass production solutions for metal 3D printing:

- The Production System™ P-50 — the world’s fastest metal binder jet system, offering the lowest cost per part, featuring Single Pass Jetting (SPJ) technology.

- The X160Pro™ — the world’s largest binder jet system for the production of both metal and ceramics, featuring Triple Advanced Compaction Technology (ACT).

- The S-Max® Pro — the world’s best selling brand of sand binder jet 3D printing systems for sandcasting molds and cores for aluminum and ferrous metal castings.

- The S-Max® Flex — an affordable binder jet 3D printing system for digital sandcastings.

- The Production System™ P-1 — the world’s best selling platform for qualifying binder jet 3D printing for serial production.

- The InnoventX™ — the world’s best-selling metal binder jet system in academia.

- The Shop System™ — the world’s best-selling metal binder jet system.

- The Studio System™ — the best-selling Bound Metal Deposition (BMD) system with only two steps and the widest material selection offered in its category.

An open house to showcase the performance capabilities of the Production System P-50 will be held on Wednesday, Jan. 25. Manufacturers interested in adopting the technology can sign up to attend at teamdm.com/p-50-open-house.