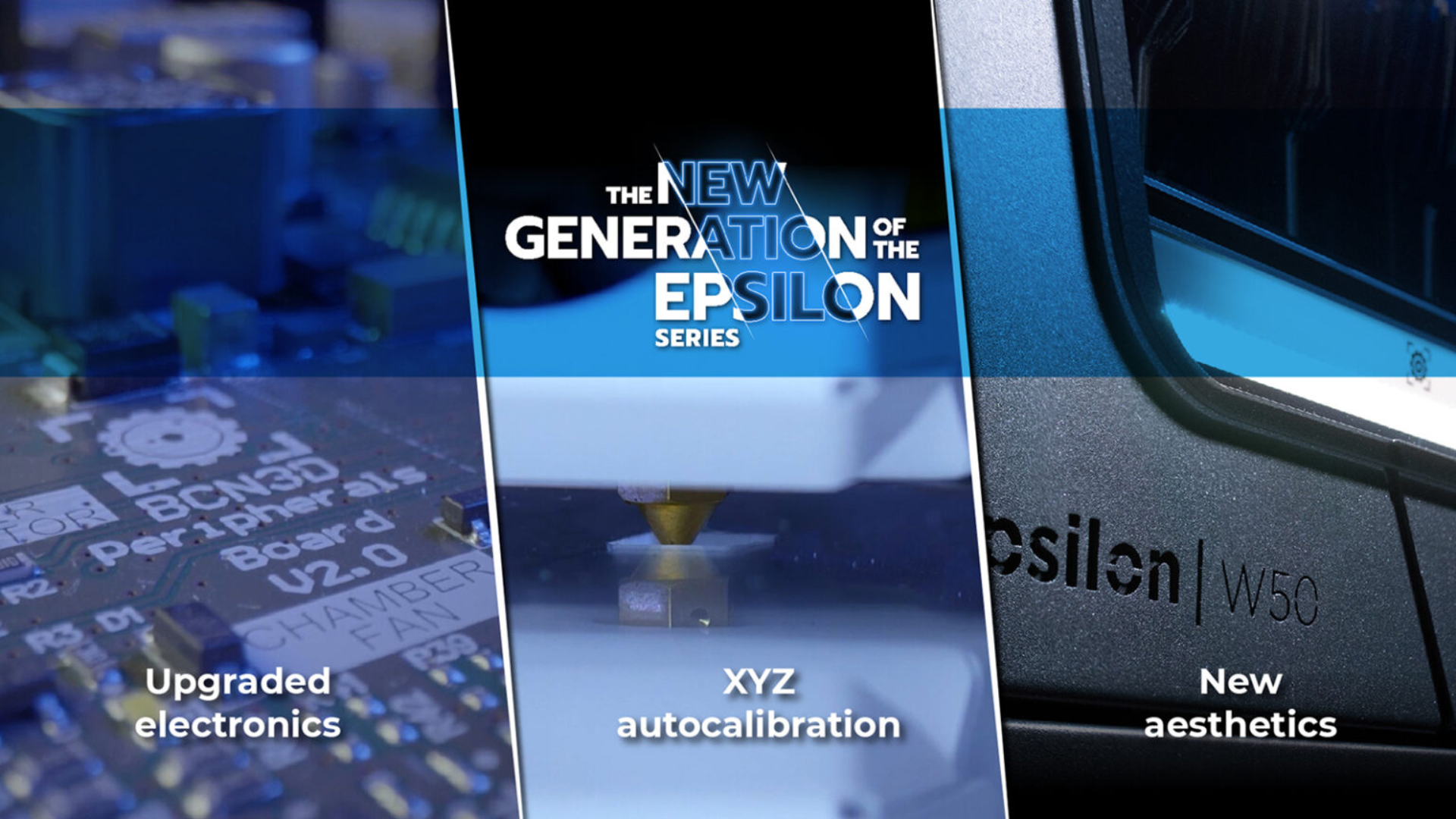

Barcelona/January 10, 2023 — BCN3D Technologies introduced an upgraded version to the Epsilon Series 3D printers. A large part of elevated efficiency can be attributed to new and improved electronics:

- New ventilation system: Previously, the ventilation system introduced cold air inside the fans with extraction towards another grid. We found that this could potentially cause turbulence in the interior, resulting in occasional inefficiencies. To resolve this, the hot air flow is now extracted from the interior and lowers internal pressure to let the interior absorb air from the outside.

- New motor drivers: Our Trinamic TMC2130 motor has been replaced with the TMC2226. Not only are these new drivers very silent, but they also perform with greater efficiency and better engine torque. Whereas their predecessors required heatsinks to cool down, these new ones instead heat up very little.

- New main board: We’ve reverted away from commercial components and decided on custom-made components specially designed for our products. These have been concentrated into one single board, as opposed to being formed of several commercial pieces implemented in various areas of the printer. This significant reduction offers a simpler and in turn more efficient main board.

One feature highly anticipated is local network access: an internal web server allows you to access it via its local IP address; send files, monitor, pause and cancel prints jobs remotely. This can also be enjoyed by owners of previous Epsilon versions after a firwmare update.

Autocalibration XYZ is another recently added feature. This automatic process can reduce printing set-up time from 40 minutes to just 6. Plus, this technology takes away dependence on human criteria, reducing room for error and guaranteeing a correct first layer adhesion every time. This calibration process is done by measuring multiple points to automatically adjust the printing surface height and (XY) offset between both nozzles. For Epsilon Series printers equipped with Independent Dual Extrusion System (IDEX), the XY alignment of the two toolheads had to be taken into account. This is done through the use of a square located at the back of the printing surface. The toolheads use this small opening to touch the sides with the hotends, calculate their positioning on both the left and right axes, and subsequently calibrate the right offsets between them. This XY alignment ensures they are perfectly aligned and avoids any crossovers or shifting layers when printing in dual mode..