The future of aerospace and defense research is predicated on advanced material capabilities. Recent developments in 3D printing technology and the introduction of composite-based additive manufacturing (CBAM) from Impossible Objects is now being adopted by major defense institutions to print strong, lightweight structures for legacy systems and future product development applications.

The Miller Advanced Research and Solutions (MARS) Center at Hill Air Force Base in Utah just upgraded their current CBAM system and envisions a big opportunity for composite-based additive manufacturing. Join Steve Hoover, Impossible Objects CEO, February 6th livestream of AM News LIVE to learn more about the relationship with MARS and why CBAM is a game changer for the aero/defense market.

January 26, 2023 (Northbrook, IL) – Weber State University is using 3D printing to advance its research on composite materials that support northern Utah’s aerospace and defense ecosystem.

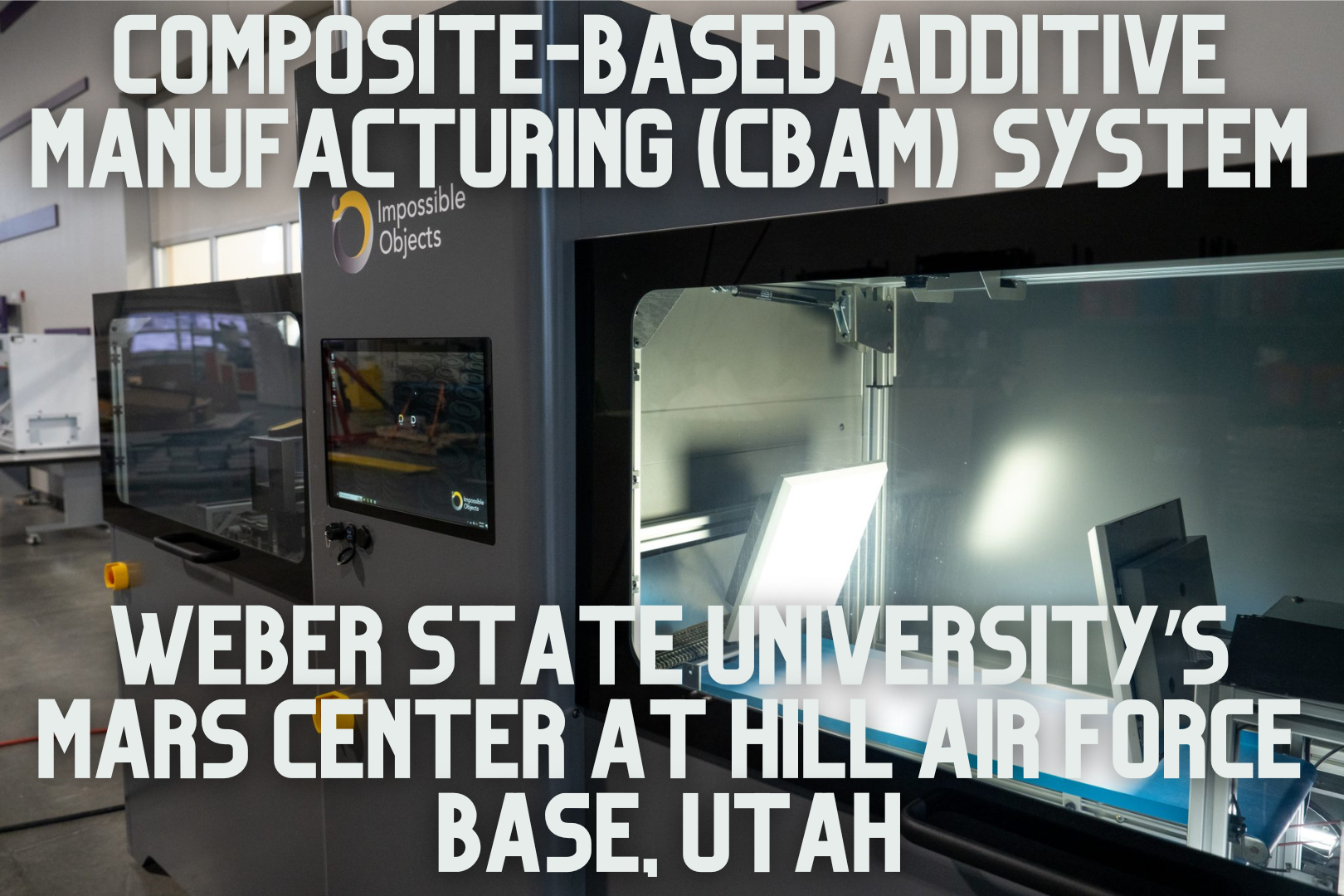

The university’s Miller Advanced Research and Solutions Center recently upgraded and installed the Impossible Objects Composite-Based Additive Manufacturing system, or CBAM-2. The machine prints composite materials that can then be used to design parts for a range of high-tech applications.

Located near Hill Air Force Base, Utah, the MARS Center brings together Weber State students and faculty with industry experts who can apply innovative solutions to real-world problems, especially in the realm of national defense.

“Composite materials are of high interest to the military, and the ability to 3D print those parts on demand with CBAM gives us an advantage to participate in more projects and recruit the best talent,” said David Ferro, dean of WSU’s College of Engineering, Applied Science & Technology.

Ferro said Weber State has a long history with Impossible Objects and believes the new system – a leap in technology from the center’s previous CBAM printer – will be a valuable tool in aerospace research among academia, defense and commercial partners.

“We’ve used this technology to print parts for legacy aircraft, aging jets that need replacement parts or tools that aren’t in production anymore,” said Devin Young, grant writing and research specialist at WSU, who works at the MARS Center. “CBAM makes parts that are lighter and stronger than some of the other methods out there, and it does it faster.”

Young said a recent example of 3D-printed parts via Impossible Objects includes a strap that keeps first-aid kits secure inside aircraft currently flown by the U.S. Air Force.

“We’ve found a range of uses for this technology, from large aerospace companies to small local businesses,” Young said.

Steve Hoover, Impossible Objects CEO, said the CBAM system’s Carbon Fiber PEEK 3D printed material achieves excellent mechanical properties and is a cutting-edge alternative for aluminum prototyping, tooling, spares and repairs.

“The MARS Center is at the forefront of aerospace and defense research,” Hoover said. “We’re proud that they’ve selected CBAM technology, and have already engaged in several projects that have exciting potential for the Department of Defense, Department of Energy and other industrial partners.”

The MARS Center opened in August 2022 thanks to a $3.5 million donation from the Larry H. & Gail Miller Family Foundation. The CBAM 3D Printer from Impossible Objects is among the first advanced manufacturing technologies to be installed and used at the new facility.

About Impossible Objects

Impossible Objects, a 3D printer and materials company, was founded with the belief that materials science inventions would enable 3D printing to revolutionize the world in the same ways computers and the internet have revolutionized the way we live, work and play. Impossible Object’s CBAM technology combines the production rate of conventional manufacturing with the design flexibility of 3D printing to create high-performance materials at break-neck speeds. These advanced composite materials are lightweight, strong and ideal for a range of industrial applications. By removing the barriers, we’ve unlocked new opportunities to reshape and rethink manufacturing.

About Dr. Stephen Hoover

Dr. Hoover is CEO of Impossible Objects – a 3D printing company whose technology and products are bringing 3D printing from prototyping to manufacturing.

Steve has a long history in research, innovation and product development in areas ranging from digital printing and 3D printing to AI, transportation, healthcare, energy and cybersecurity. For over 20 years and until April of 2019 Hoover had a variety of technology leadership roles at Xerox which included CTO for the entire corporation and CEO of PARC, a Xerox company. Steve led the technology development and productization of multiple products and technologies that revolutionized commercial printing and publishing, and which created Xerox’s multi-billion commercial digital printing business. In addition to that he also developed new technologies and products in new areas for Xerox ranging from document management and services to transportation analytics and IoT to digital packaging and 3D printing. Serving as Xerox PARC CEO for six years, Steve transitioned PARC to be a leader in open innovation by creating multiple strategic innovation partnerships and collaborations and spinouts of PARC developed technologies as well as productizing multiple innovations for Xerox’s core and new businesses.

After leaving Xerox as CTO in 2019, he served until March 2022 as the Katherine Johnson Endowed Executive Director of the Global Cybersecurity Institute where he served as the founding director at Rochester Institute of Technology from 2019-2022. During that time, he also co-founded a startup focusing on using computer vision to improve fine art sales and art identification – Artify.ai – as well as advising other startups and small companies in areas ranging from cleantech to data enabled HR services.

Steve earned his Ph.D. and Master of Science from Carnegie Mellon University as an AT&T Bell Labs fellow and a Bachelor of Science degree from Cornell University. He has seven patents.

Hoover currently serves on the Board of Directors of Consumer Reports and the Dean’s advisory council of the College of Engineering at Carnegie Mellon University. He has previously served on the Board of Trustees of RIT, the Board of Directors for the Rochester Museum and Science Center, including leading its K-12 STEM Education Task Force; and has been a regional Board Member of FIRST Robotics, an organization which inspires young science, technology, and engineering leaders through mentor-based programs.

About Weber State University

Weber State University is renowned for excellent teaching, accessible educational opportunities and its enduring presence in northern Utah. Weber State serves more than 29,000 students from all walks of life and offers 225+ degree programs, including 20 graduate degrees. Weber State is a premier academic partner for Utah’s aerospace and defense industries. WSU students in engineering and computer science are poised to become leading experts in technology that provides innovative solutions to real-world problems in national defense and beyond. For more information, visit weber.edu/east.