The Girl Gang Garage shop in Phoenix, AZ is an anomaly… the three classic car builds inside were built by all-woman teams, led by ASE Certified Master Technician and MotorTrend star Bogi Lateiner. Even more unusual, the most recent build dubbed “Iron Maven” includes custom 3D printed components in many parts of the vehicle.

The Iron Maven is an ambitious build that combines the body from a 1961 Volvo PV544 and the chassis and drivetrain from a 2019 Volvo S60 Polestar. The PV544 is a tiny classic car with a design that was vintage even in 1961, featuring curved styling, squared off fenders, and unibody construction. The S60, a much larger vehicle, is a modern plug-in hybrid.

To kick off the project Bogi reached out to Stratasys which sponsored an onsite F370 FDM printer, support removal tank, and filament, and connected the team with local reseller PADT which also supported 3D scanning for the project. Pam Waterman, applications engineer at PADT and Phoenix Ambassador for Women in 3D Printing, worked extensively on 3D scanning the PV544 body and components from the S60 as well as training the team on running the F370.

Through Women in 3D Printing, Girl Gang Garage put out a call for support on design and CAD modeling for the vehicle. Anne Pauley, mechanical engineer, and San Francisco Women in 3D Printing Ambassador, joined the project to focus on component design. She recommended Fusion 360 as the CAD tool for the project, and through the Autodesk Technology Centers residency program Girl Gang Garage was able to get access to software and support from the Autodesk team.

Why 3DP?

Additive manufacturing is a relatively new addition to the Girl Gang Garage toolkit. Bogi’s interest in incorporating 3D printing into the latest vehicle build is twofold: quickly creating fully custom components and providing new educational opportunities.

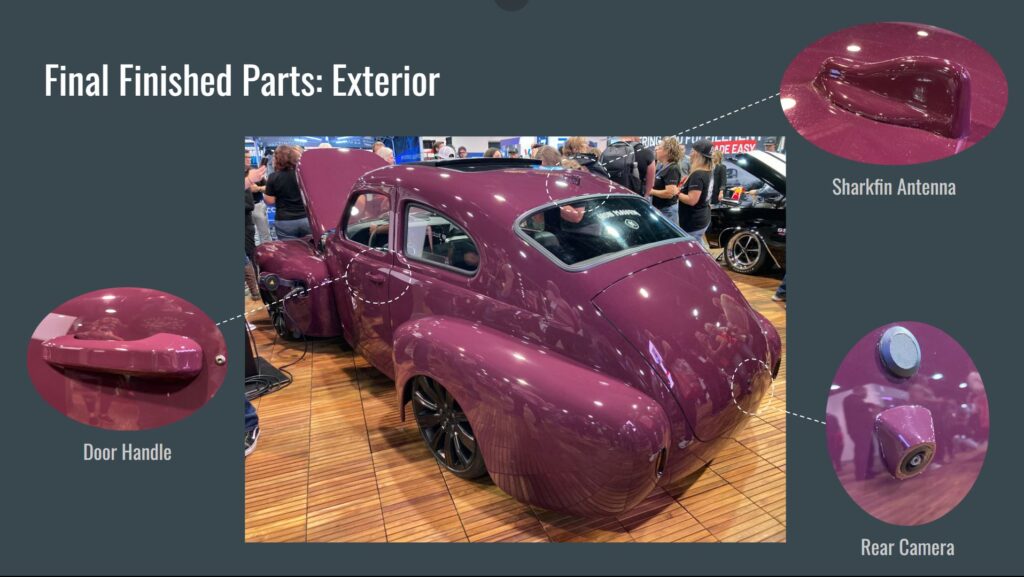

Prototyping speed was critical to the Iron Maven build, and being able to 3D print multiple iterations a day allowed the team to quickly refine the fit and appearance. The team’s goal was to blend modern electronics seamlessly with the PV544 which meant getting a perfect fit and matching the curved vintage style. Every part printed for the Iron Maven is completely custom for the vehicle. Matching the style of the unique hand built PV544 body required a complete redesign of every part.

Bringing additive manufacturing into the Girl Gang Garage shop was about more than just the build. In collaboration with Autodesk, the first CAD and 3D printing workshop was held in the shop taught by the Fusion 360 and Autodesk Technology Centers teams. The 3-day class was designed for complete beginners, so participants were able to quickly go from downloading the software to making 3D printed parts like the ones used on the Iron Maven. With newfound CAD skills from the workshop, Bogi herself modeled and 3D printed a critical part for the build, an adaptor needed to retrofit a new more compact suspension onto the PV544.

3D Scanning to CAD to 3D Printing

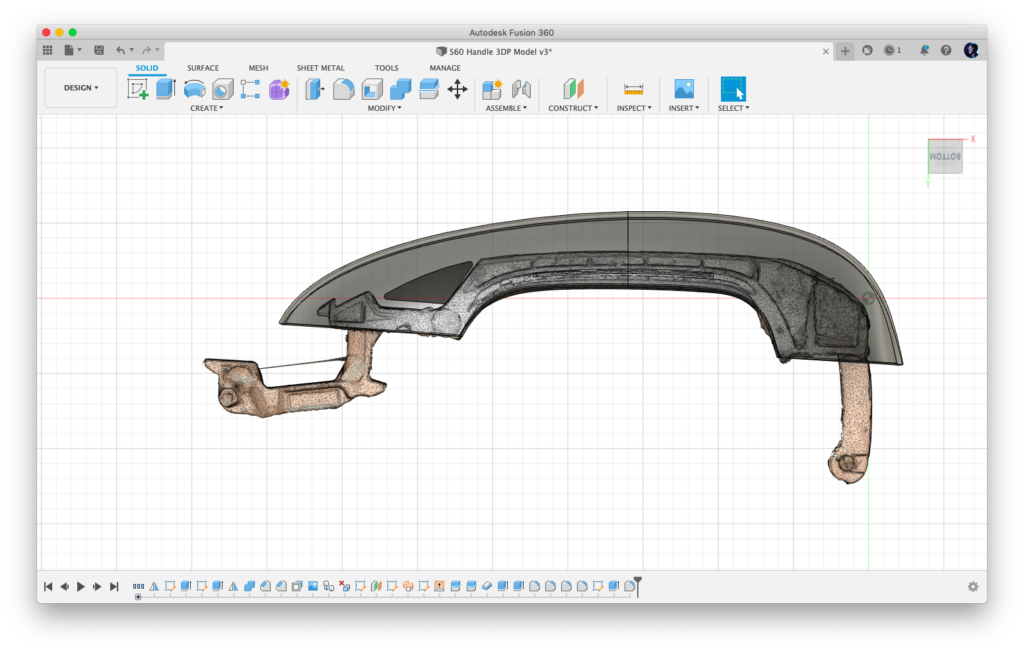

To start designing parts and plan the major body rework, the Girl Gang Garage team needed to reverse engineer reference geometry for both individual components and the full PV544 body. Using PADT’s handheld TScan Hawk scanning equipment and GOM software tools, Pam was able to create point clouds and convert them to STL reference files which could be used in CAD.

Pam Waterman scans the ‘61 PV544 body

The new parts needed to match the unique aesthetic of the ‘61 PV544 and the functional needs of integrating modern components from the 2019 S60. Using the 3D scans, Anne modeled and prototyped mechanical fit checks for key features such as the handle snap fits, camera mounting, and antenna electronics to get a perfect fit. She then modeled and iterated on the outer design of the housing using the F370 printer until the team felt like the designs matched the PV544 style.

Scan to Model to Prototype: Custom 3D printed door handles for the Iron Maven

SEMA Reveal

The Iron Maven made its public debut at SEMA Show 2022 in Las Vegas, which Bogi called the “Super Bowl of car shows”. The excitement at the big reveal event in the BASF booth was amplified by the group of around 40 women who had worked on the build and traveled to SEMA to see the final result. The cheering from the packed crowd when the cover came off the car could be heard around the entire expo hall.

Takeaways

Women comprise about 12% of the additive manufacturing industry according to the 2021 Worldwide Additive Manufacturing Salary Survey, and 9.6% of automotive repair & Maintenance employees. The type of opportunities that Girl Gang Garage is creating allows women of all backgrounds to learn about the automotive trades, and now additive manufacturing as well, in an inclusive and welcoming space.

The Iron Maven build has put additive manufacturing on some of the biggest stages in the automotive world, demonstrating how 3D printers may become the next essential tool for custom car restoration. As for Girl Gang Garage, Bogi Lateiner says that the group will be continuing to use additive manufacturing on future builds, creating new opportunities for women in the group to gain hands-on experience with CAD and 3D printing.