Watch the AM News LIVE Coverage

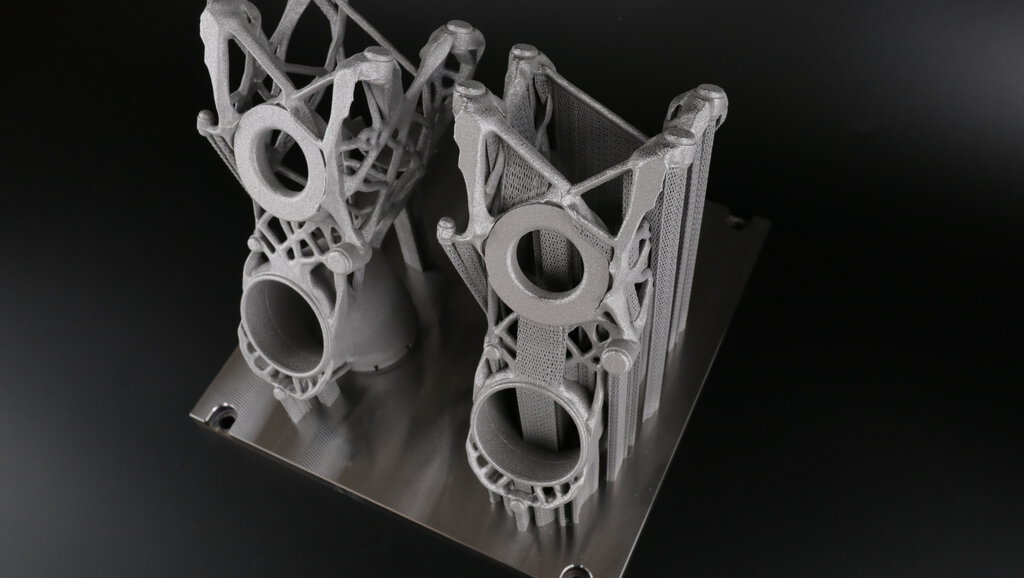

Committed to the advancement and adoption of metal additive manufacturing (AM), EOS has launched its Smart Fusion software technology for laser powder bed fusion (LPBF) metal 3D printing that automatically adjusts laser power in real-time. The technology eliminates the need for most support structures, minimizes material use, reduces post- processing requirements, and lowers the cost-per-part (CPP) for metal AM applications.

Smart Fusion intuitively detects potential build problems, auto-adjusts the laser power, and eliminates wasted time and resources typically associated with “trial and error” additive manufacturing. Unlike current technologies, Smart Fusion’s real-time capabilities are achieved without adding significant build-time.

Customer Beta testing of the Smart Fusion solution has consistently resulted in performance that is two to five times (2x-5x) faster than the leading competitors in the metal AM market. Lower CPP is a primary business driver for the adoption of Smart Fusion. Removing the need for support structures in metal AM makes for a more attractive business case. EOS partnered with several organizations during Smart Fusion’s testing phase where its speed and performance were validated.

When we learned about Smart Fusion and started to test it several month ago, we knew it would be a game changer. Not only does it significantly reduce the part cost, but it is also a facilitator in the use of optical tomography which, in our view, is a key element to introduce AM for serial production. Over the past few months, we have developed several products with EOS which really show the potential of Smart Fusion.

Stefan Seidel, Chief Technical Officer at Pankl Racing Systems, manufacturers of auto racing, aerospace, and other high-performance applications.

How it Works

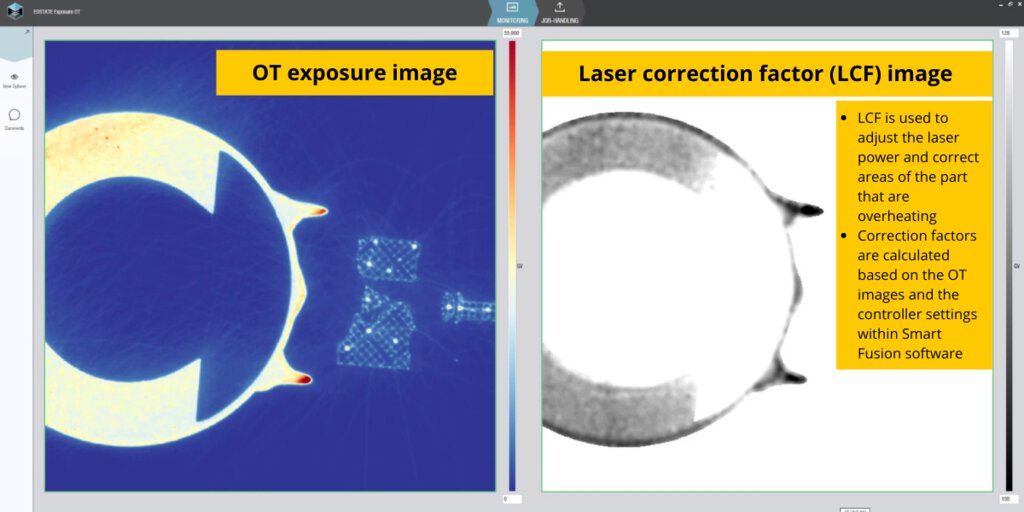

Smart Fusion measures the amount of laser power (energy) which is absorbed by the powder bed. A special high-resolution camera overlooking the build chamber monitors each layer’s meltpool emissions via proprietary technology and data is fed back to the laser where it is adjusted. This results in homogeneous energy distribution across the whole build platform thereby reducing stress in the parts and avoiding metal overheating and movement in undesired directions.

At its core, Smart Fusion pairs with EOS’ existing monitoring solutions and employs advanced algorithms to monitor the build layer-by-layer providing for more homogeneous, consistent parts. From a dataflow perspective, EOSPRINT prepares the data which is sent to the 3D printer, Smart Fusion then works with EOSTATE and its Optical Tomography (OT) camera to monitor, measure, and adjust the lasers via EOSYSTEM.

Smart Fusion is another important breakthrough for metal AM, especially for those organizations with highly engineered applications, such as energy, space tech, mobility, and aerospace. Other solutions in the market have significant drawbacks such as slower build times, and a need for an expert to make sure it works. Smart Fusion offers an industrialized solution that is faster, flexible, and more accessible.

Mirco Schöpf, EOS product line manager, software

Another organization that piloted Smart Fusion engineers and manufactures hardware for the space industry. They compared Smart Fusion head-to-head with a leading competitive technology and the comparative builds proved Smart Fusion to be more than twice as fast and delivered better part qualities.

Smart Fusion lists for €27,000/$29,262 (EOS M 290) and €38,000/$41,184 (EOS M 300-4, and EOS M 400-4), requires the Smart Monitoring System package, and is available now for on the following EOS system and materials:

The beauty of Smart Fusion is that it is incredibly flexible, easy-to-use, and will work with the majority of customer applications out-of-the-box. We challenged our team to mitigate one of metal AM’s significant challenges with a unique software solution and we could not be prouder of the results.

Mirco Schöpf, EOS product line manager, software