AM materials development began when the first additive manufacturing machines were commercialized. 2021 was no exception. The AM/3DP community saw new filaments, powders and resins to address the performance needs of expanding applications for metals, polymers, and composites.

Lauralyn McDaniel

content by Lauralyn McDaniel

2021 Technology Roundup: Software

The growth of software for additive manufacturing continued in 2021. New features, new platforms, and new integrations offered solutions throughout the AM process; from design to post processing. Some of the notable announcements in 2021 included partnerships and integrations into comprehensive platforms.

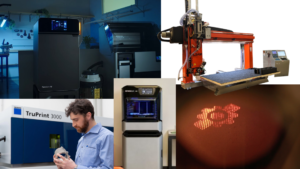

2021 Technology Roundup: Hardware

2021 was a busy year for additive manufacturing machine manufacturers. New 3D printers were launched covering every process and material category as well as size. From creating parts that are 4’ tall down to 15 microns, new options became available for the AM/3DP community covering applications in aerospace, automotive, energy, medical, and more.

What About Prototyping?

With a group of technologies that was referred to as rapid prototyping in its earliest days, there doesn’t seem to be much discussion about prototyping today. Some may wonder if it is even a significant part of the applications of additive manufacturing. What about prototyping? Is it still a thing? More than 15 years ago, […]

AM Innovation Awards 2021

ASME Recognizes “Best-in-Class” Additive Manufacturing Technologies with First AM Innovation Awards The AM Tech Forum powered by ASME concluded with a much-anticipated awards presentation based on the day’s nearly 40 technology demonstrations. These solutions covered every application area and industry, showcasing machines and processes, materials, software, and measurement and analysis. Winners were chosen based on multiple […]

An AMazing® Exclusive Q&A Interview with Anteneh Kebbede, GE Research Center

GE (NYSE:GE) researchers recently announced the use of a process called “cold spray,” in which metal powders are sprayed at high velocities to build a part or add material to repair an existing part. Cold spray is part of GE’s expanded additive manufacturing toolkit. GE researchers are developing new ways to repair and even build […]